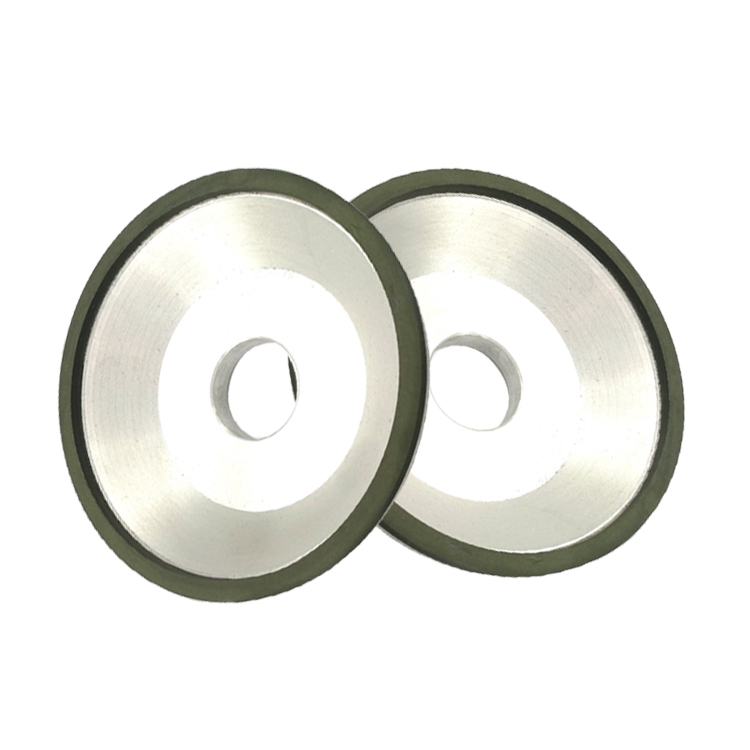

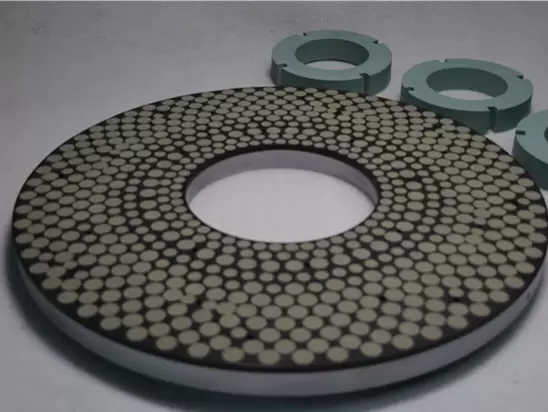

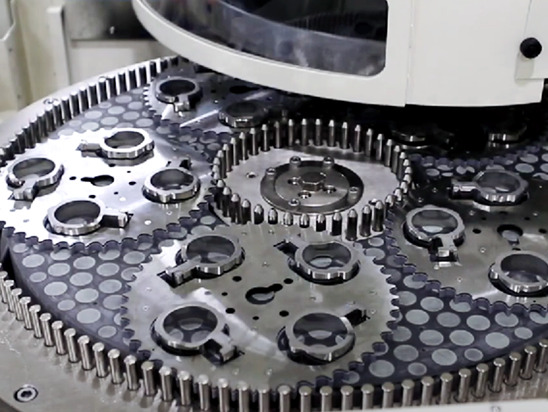

This Grinding Wheels used to Grind both sides of Thrust Washers , Automotive Pump Parts , Washers , Compressor Valve Plates , Carbide Inserts and for Cutting Tools , Automotive component Industries , Gear Industries , Compressor Industries etc.

|

||||||||||||

Advantages of double-end grinding wheels

1.Fast Grinding, high grinding efficiency

2.High abrasive,wheel abrasive layer is very abrasive

3.Grinding force is high and big,grinding temperature is low

4.After grinding,workpiece can reach high precesion on tolerance,reach good surface roughness,good flatness

Application of double-end grinding wheels

Compressor parts: Air conditiAdvantages of double-end grinding wheelson compressor blade, piston, cylinder, refrigerator compressor valve plate, etc.

Hydraulic elements: Blade pump,steering valve, plunger pump, gasoline pump,hydraulic motor, etc.

Engine parts Internal combustor part, booster pump part, oil nozzle/ oil pump part, etc

Various hard alloy blades, high precision bearing, sealing piece, watch part, ceramic valve core, magnetic material, etc