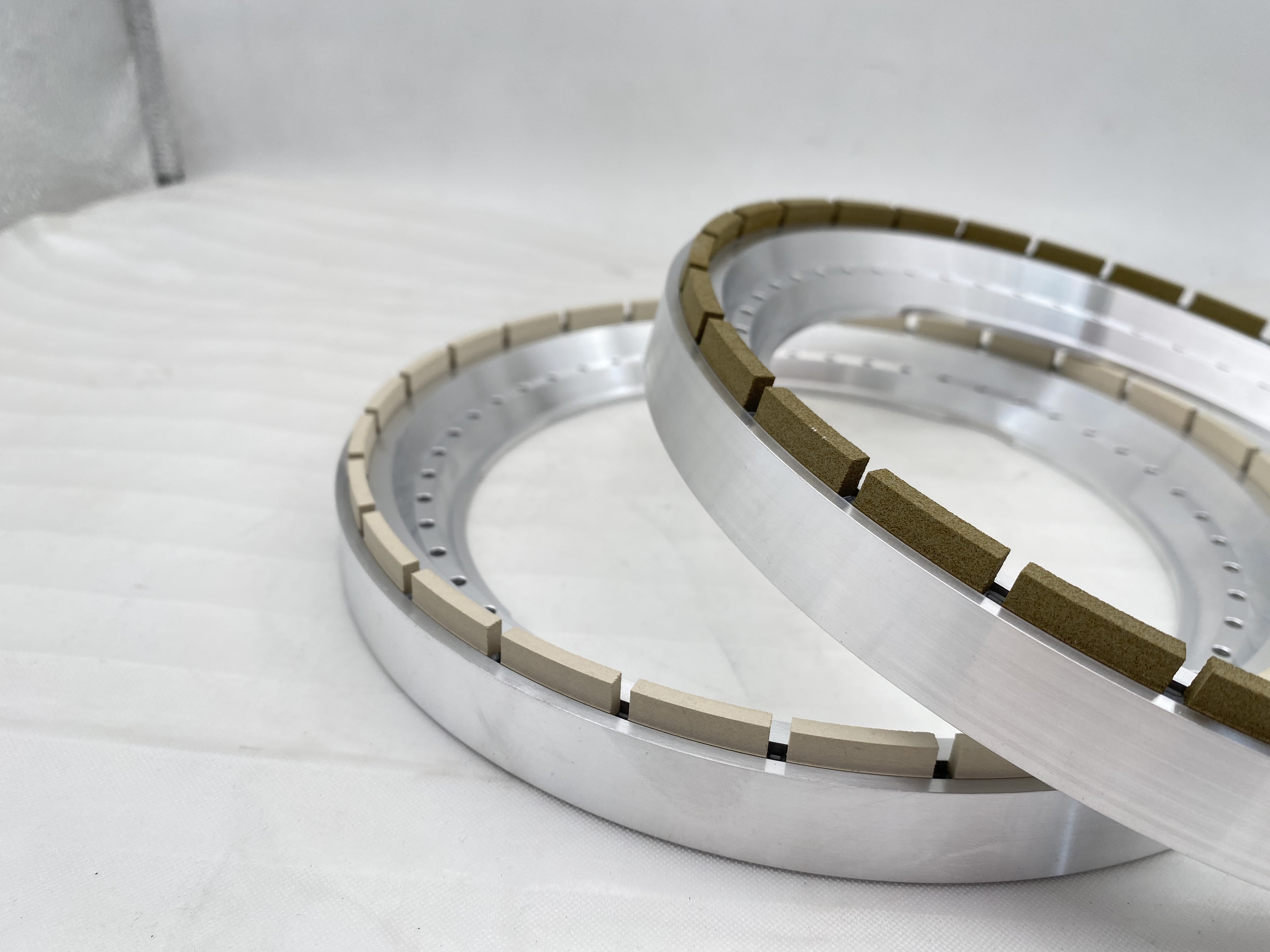

Vitrified Bond Back Grinding wheel

This series of vitrified diamond wheel is mainly used for back thinning and precision processing of semiconductor wafers, discrete devices, integrated circuit substrate silicon wafers, and raw silicon wafers.

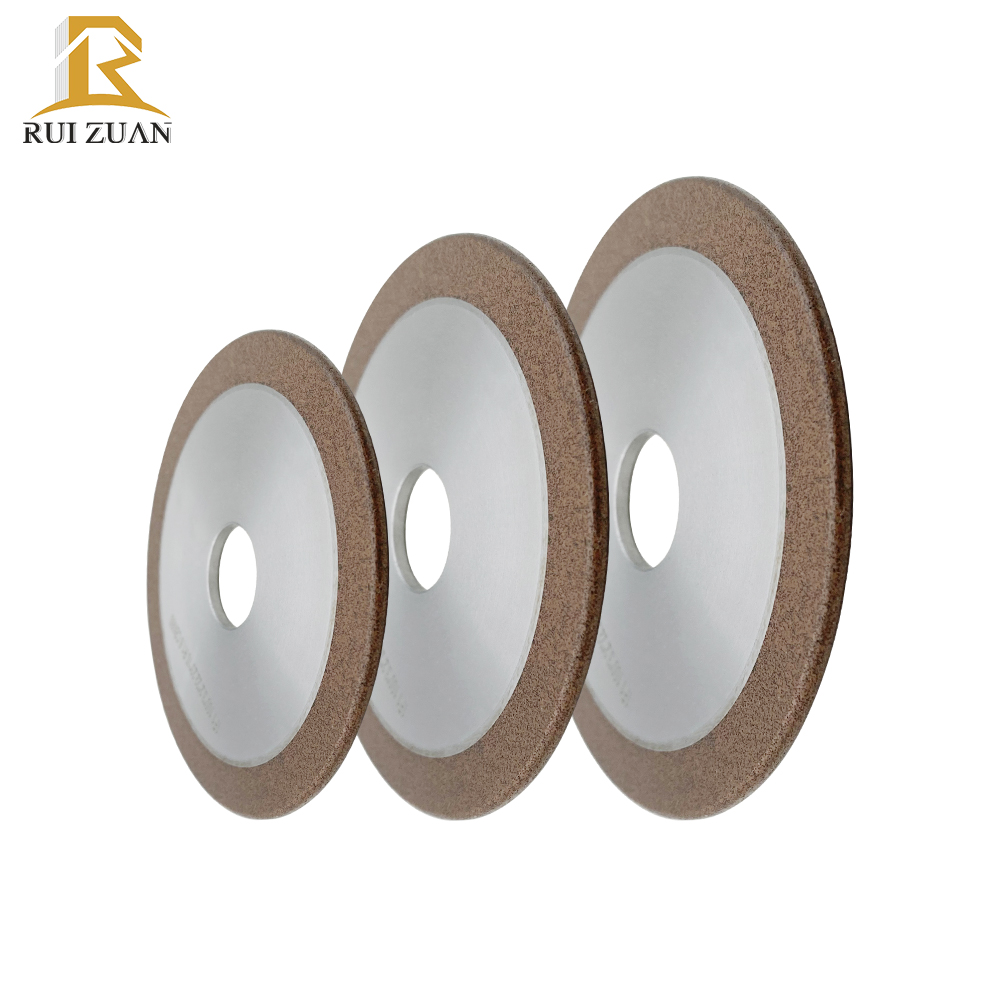

Resin Bond Back Grinding Wheel

Resin bond back grinding wheel is made from thermoset resin and diamond, which is used for silicon wafers, sapphire, gallium nitride, gallium arsenide.

|

||||||||||||||||||||||||||||||||

Advantages of back grinding wheel

1. With low damage and high quality

2.Nodeless consecutive processing is possible by the superior sharpness

3. It helps minimize processing damage,improve processing efficiency and reduce processing cost, and is customizable according to customer needs

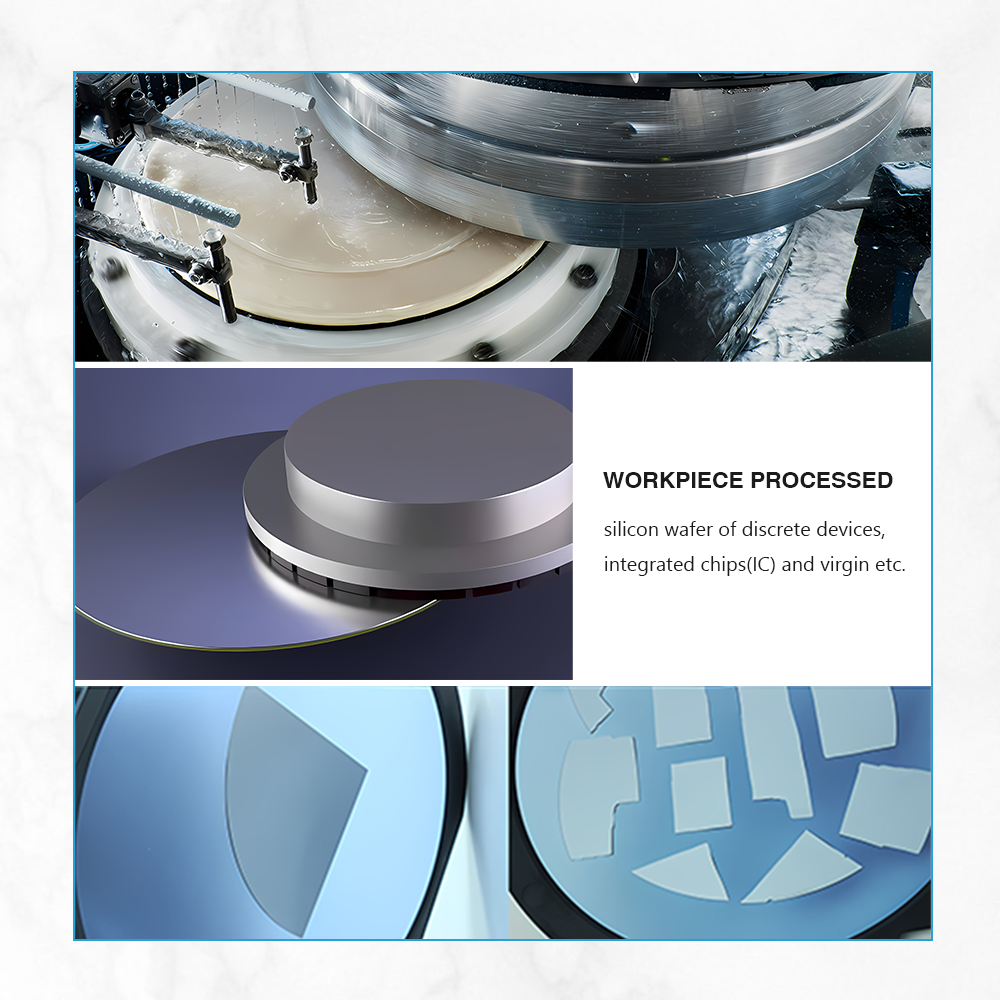

1.Applications of back grinding wheel:

Back thinning, front grinding and fine grinding of discrete devices, integrated circuit substrate silicon wafers, sapphire epitaxial wafers, silicon wafers, arsenide, GaN wafers, silicon-based chips, etc

2. Workpiece processed: silicon wafer of discrete devices, integrated chips(IC) and virgin etc.

3. Workpiece materials: monocrystalline silicon, gallium arsenide, indium phosphide, silicon carbide and other semiconductor materials.

4. Applications: back thinning, rough grinding and fine grinding

5.Applicable Grinding Machine:The back grinding wheels can be used for the Japanese ,German, American, Korean and other grinders ( Such as NTS, SHUWA, ENGIS, Okamoto , Disco, TSK and STRASBAUGH grinding machine, etc ).