Valve Seat Abrasive Grinding Wheel

|

||||||||||||||||||||

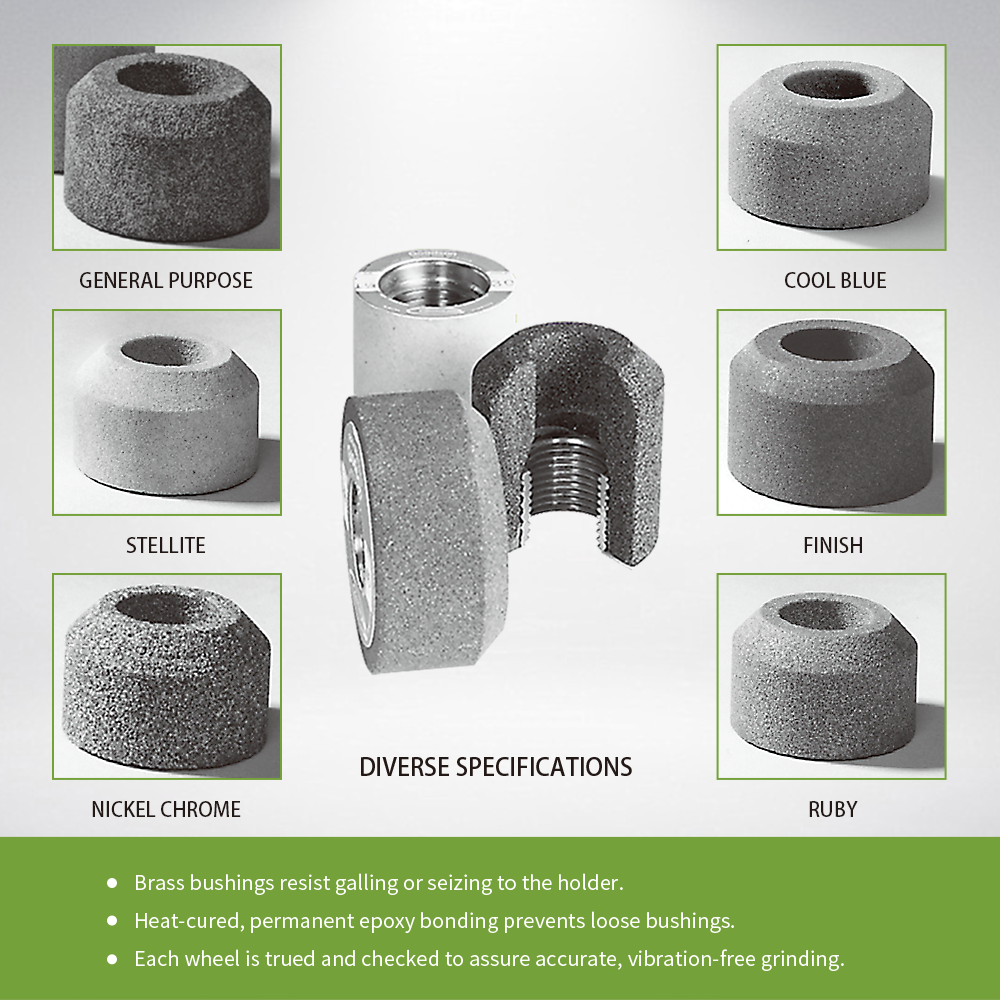

1.Stellite is used in many various components and is composed of 75 to 90% Cobalt and 10 to 25% Chromium with or without small amounts of other metals added. It is used especially for cutting tools, hard wear-resistant surfaces, surgical instruments, and cutlery.

2.Nickel Chrome is defined as a stainless steel containing 8% Nickel and 18% Chromium. Nickel Chrome is very resistant to wear and chemical reaction. It’s used in valve seats where we have a severe duty application such as air compressors, diesel earth movers and even some over the road trucks.

3.Cool Blue is an abrasive spec created by specifically for grinding the Copper Beryllium valve seats found in high-performance applications.

4.Ruby Stone is our best aftermarket replacement for the original Black and Decker spec. This spec was designed for use as a general purpose wheel to grind most seat alloys from the late 60s to the early 80s.