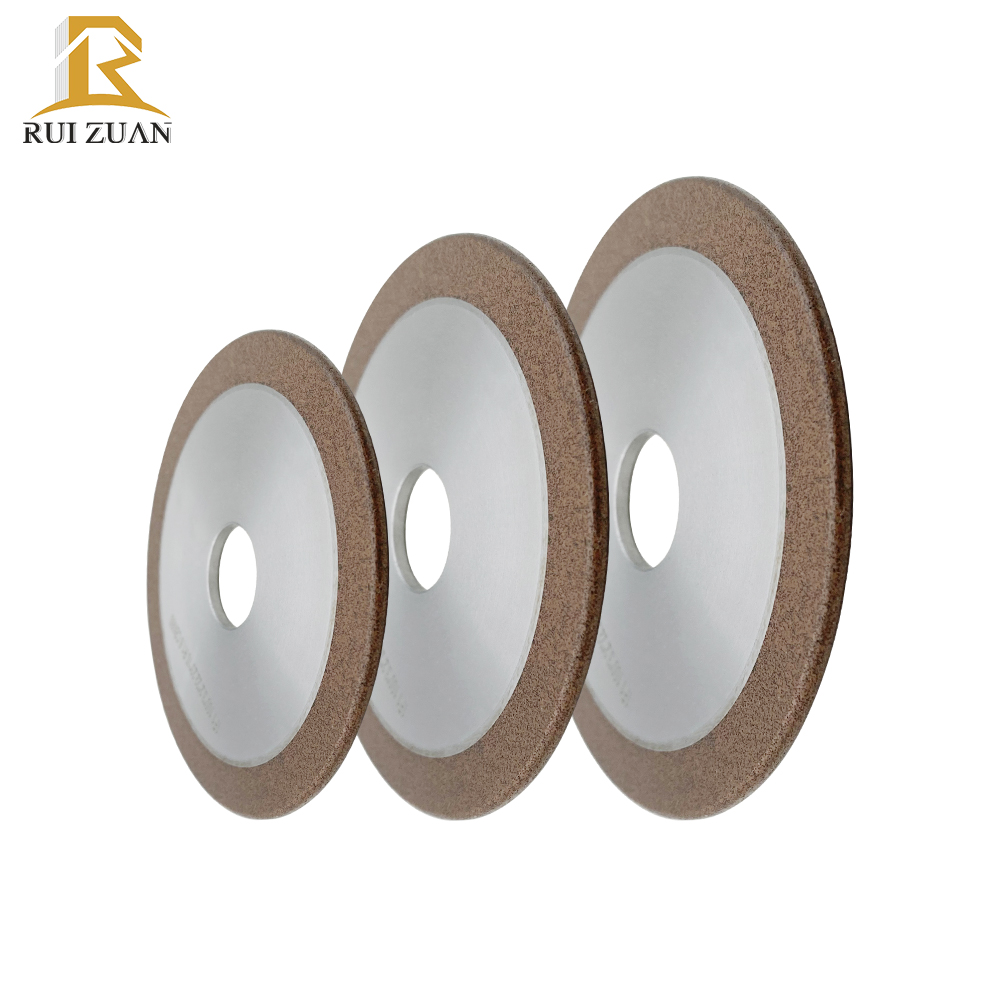

Products Description

Resin Bond is the commonest bonding both in traditional abrasive wheels and Superabrasives (Diamond and CBN) grinding wheels. Resin bond can make the abrasive tips exposed quickly. It is applied to be used wet or dry for most tool making, resharpening and toolroom reconditioning applications and also in grinding and polishing glasses, stones, silicon and many other non-metal materials.

| Features | Grinding Method | Industry |

| Economy - Cheapest Bond | OD Grinding | Tool Grinding & Sharpening |

| High Efficiency | Surface Grinding | Woodworking Tools |

| High Stock Removing Rates | Profile Grinding | Oil & Gas Tool |

| Good durability | ID Grinding | Knife & Blades |

| Good Shape retaining ability | Cutting | Mould and Die |

Abrasives

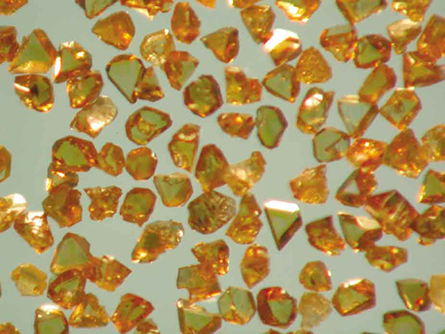

Generally, Diamond and CBN are called “Super Abrasives” or “Superhard Materials”.

Obviously, the wheels manufactured with these abravises are called Diamond or CBN grinding Wheels.

Diamond

| In general, diamond is used to grind non-ferrous materials |

| • Cemented carbide(Tungsten Carbide) |

| • Glass |

| • Ceramics |

| • Fiberglass |

| • Plastics |

| • Stone |

| • Abrasives |

| • Electronic components and materials |

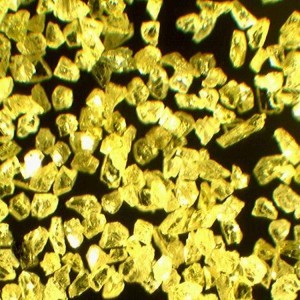

CBN

| CBN is used to grind ferrous materials. |

| • High-speed tool steels |

| • Die steels |

| • Hardened carbon steels |

| • Alloy steels |

| • Aerospace alloys |

| • Hardened stainless steel |

| • Abrasion-resistant ferrous materials |

RZ Resin Bonds Introduction

After years’ developing, RZ developed bonding for different application.

| Bonds | Features | Application | Grinder | Industries |

| B109 |

Economy Resin Bond Wet & Dry grinding Sharp |

Tool Sharpening |

Manual Semi-Automatic |

Woodworking Metalworking Knife Blades |

| B102 |

Advanced resin bond Wet and dry grinding Durable |

Tool Grinding, Tool Sharpening |

Manual Semi-Automatic Full-Automatic |

Woodworking Metalworking Knife Blades |

| B201 |

Universal Bond for Wet grinding Wet Grinding Standard bond for quantity grinding |

Cylindrical Grinding Surface Grinding |

Manual Semi-Automatic |

Cutting Tools, Mould & Dies, Knife & Blades Oil & Gas |

| B202 |

Advanced Bond for Wet grinding Wet Grinding Advanced bond for quantity grinding |

Cylindrical Grinding Surface Grinding |

Manual Semi-Automatic |

Cutting Tools, Mould & Dies, Knife & Blades Oil & Gas |

| B601 |

Super Resin Bond for Tool grinding Bond for tool fluting & Gashing on CNC Dural Bond |

Tool fluting Tool Gashing Edge Clearing |

Full-Automatic CNC |

Cutting Tools Metalworking |

| MH11 |

Hybrid Bond Most Durable Free cut on tool fluting Bond for tool fluting & Gashing |

Tool fluting Tool Gashing Tool Profiling |

Full-Automatic CNC |

Cutting Tools Metalworking |

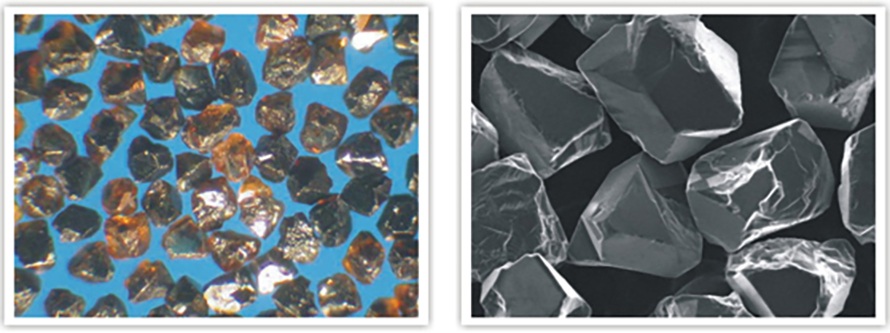

Diamond CBN Abrasive Type and Grits Selecting Charts

| CODE | Abrasives | Grits | Concentration | Hardness |

| D | Synthetic Diamond Mono-Crystal Type I |

80, 100 Roughing | 50 Most economical For broad area of contact |

H Extremely Soft Sharp |

| SD | Synthetic Diamond Mono-Crystal Type II |

120 Roughing/cutting-off | 75 Improved on Wheel Life Improved on Wheel Sharp |

K Soft Sharp |

| SDC | Synthetic Diamond Mono-Crystal Metal Coating |

150 – Combined roughing and finishing | 100 Standard Concentration |

N Standard |

| DP | Synthetic Poly Diamond | 180 – Improving finish | 125 • Form holding • For high volume grinding |

O HARD |

| DPC | Synthetic Poly Diamond Metal Coating |

220, 320, 400 for finishing | 150 Quantity Grinding Super wheel life |

|

| B | CBN Abrasives | 600, 800, 1000 1500 for polishing | ||

| BC | CBN With Coating |