Zhengzhou Ruizuan Diamond Tools Co., Ltd. is set to participate in the Grinding Technology exhibition from March 5th to 7th. Our booth number is G - 021, and the venue is Makuhari Messe, 2 Chome - 1 Nakase, Mihama Ward, Chiba, 261 - 8550, Japan.

RUIZUAN Booth Number: G-021

1.png)

What products will show in Grinding Technology?

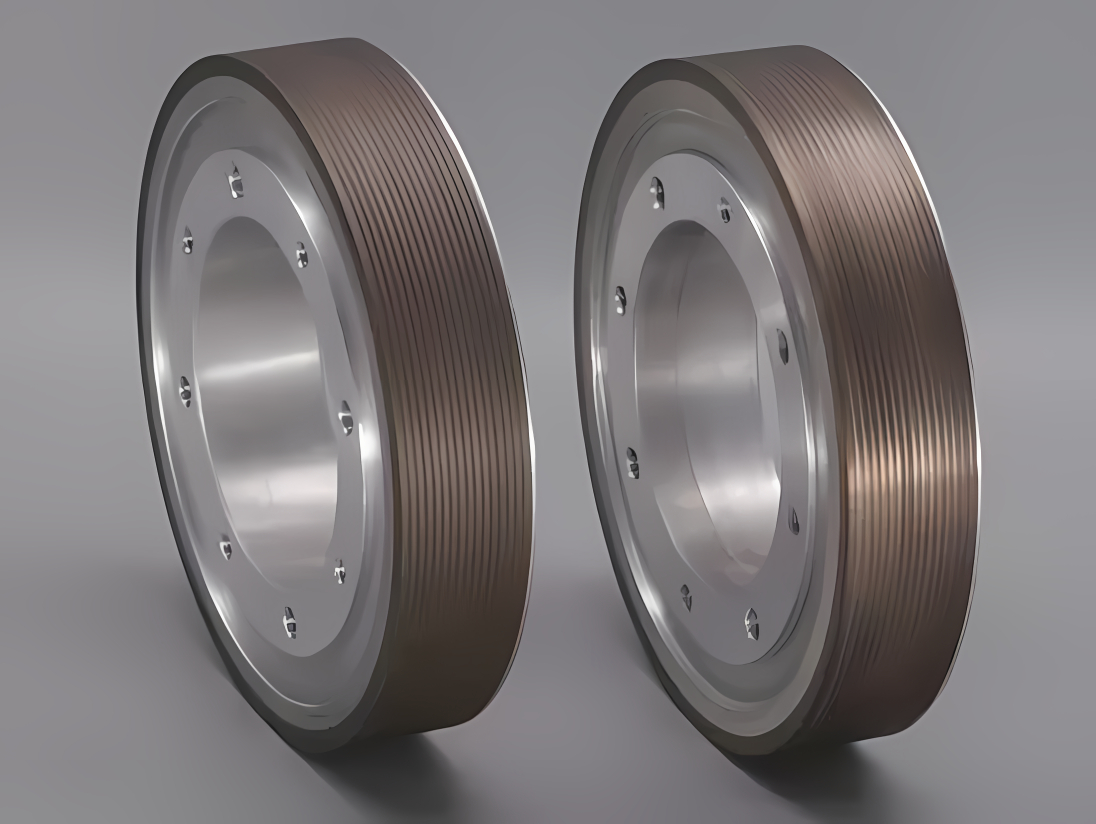

1.Semiconductor Thinner Grinding Wheel

Specifically designed for semiconductor wafer thinning. By adjusting the bond and binder, it enables the grinding of hard - to - machine materials that originally required fine grains, effectively shortening the grinding time and achieving high - speed mirror processing of wafers.

It can grind hard - to - machine materials at high speed with a mirror - like finish. It has a high - porosity abrasive grain layer, excellent cutting persistence, and can supply grinding fluid to the grinding point efficiently, enabling low - damage processing.

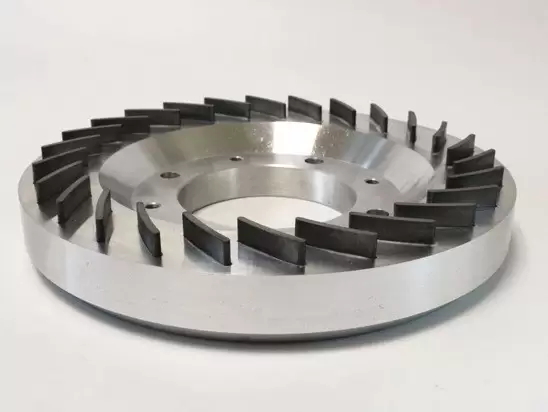

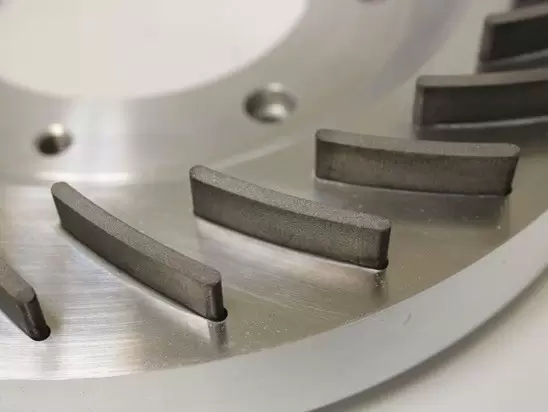

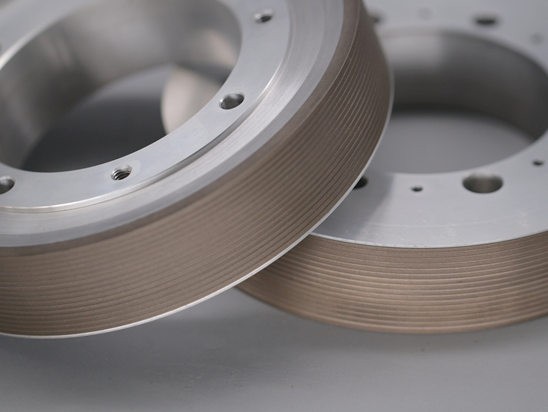

2.Metal Bond Back Grinding Wheel

The metal bond provides strong holding power for the abrasive grains, ensuring high grinding efficiency and long service life. It is mainly used for back grinding of semiconductor wafers, helping to achieve precise thickness control and surface flatness.

High wear resistance and strong grain retention. It can withstand high grinding forces and maintain stable performance during the back grinding process, contributing to high - quality wafer processing.

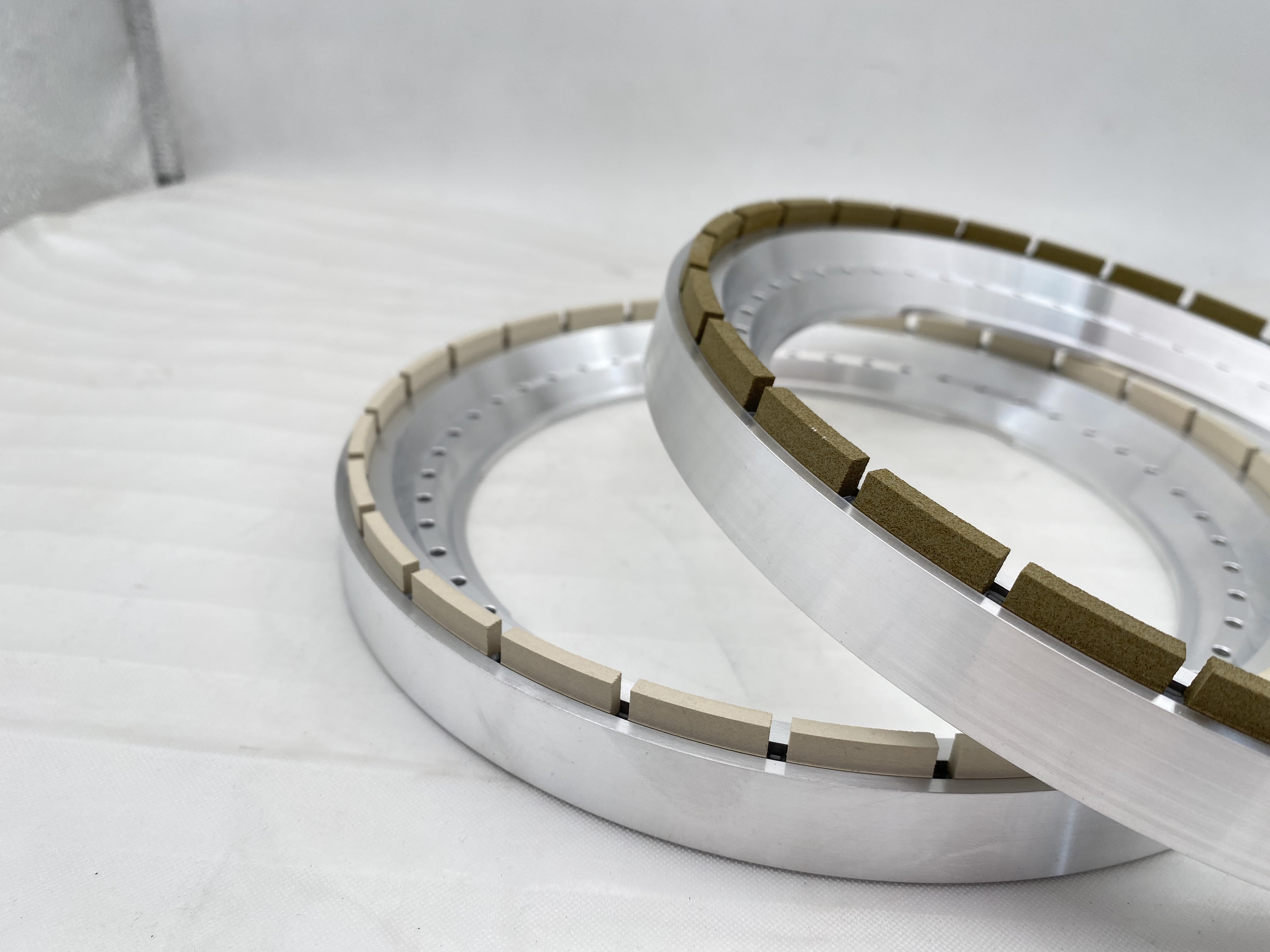

3.Metal Bond Edge Grinding Wheel

In the semiconductor industry, edge grinding wheels have strict requirements for shape accuracy, wear resistance and stable grinding ability. Through the adjustment of the binder type, particle size and concentration, the accuracy and quality of the shape required by the grinding surface can be achieved, and the grinding performance can be maximized.

It realizes excellent processing surface quality. The wheel groove shape is uniform, stable and interchangeable. It is suitable for high - speed and high - efficiency grinding, has a long service life and high cost performance. It also has good self - sharpening and sharpness.

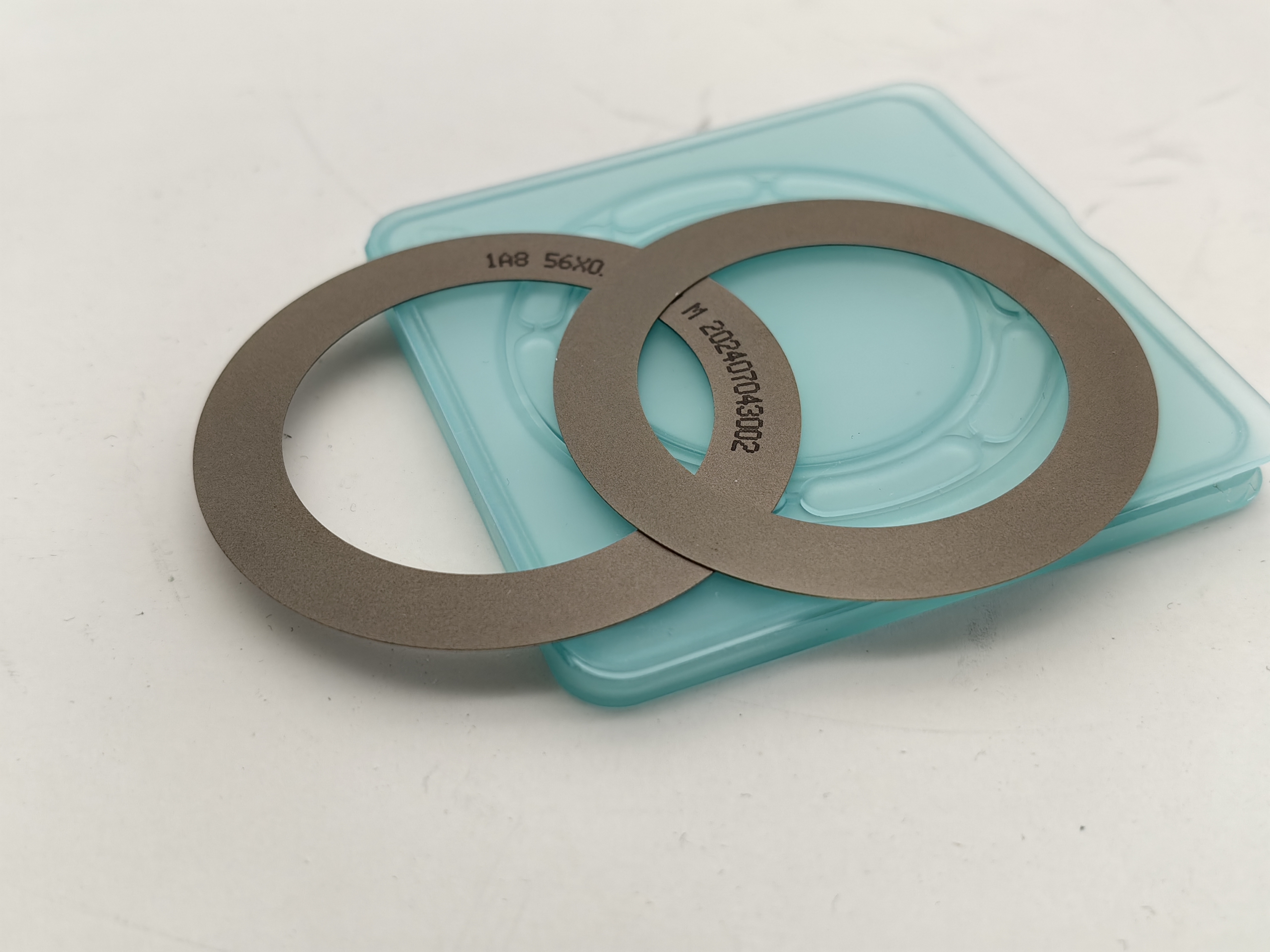

4.Diamond Dicing Blade

Manufactured through electroplating technology, the diamond grains are firmly adhered to the blade substrate. It is used for dicing semiconductor wafers, offering high precision and efficiency in cutting.

The electroplating process ensures a uniform distribution of diamond grains, resulting in consistent cutting performance. It has a high cutting speed and can achieve fine cuts with minimal kerf width, reducing material waste.

We sincerely welcome all customers and industry peers to visit our booth at the Grinding Technology exhibition. Let's explore the world of advanced grinding technology together and look forward to creating brilliant achievements in the semiconductor field.

Post time: Feb-28-2025