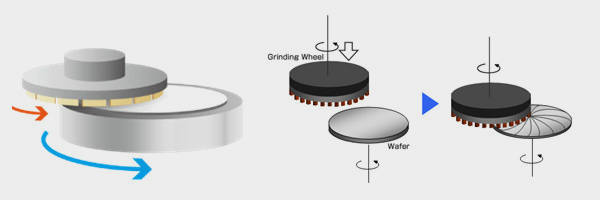

In the semiconductor manufacturing industry, wafer back grinding is a critical process that ensures the functionality and reliability of advanced electronic devices. As semiconductor technology advances, chips are becoming thinner, lighter, and more efficient. Wafer thinning is essential to achieve the desired chip thickness while maintaining structural integrity.

In the back-end process stage, wafers (silicon wafers with circuits on the front) need to be thinned on the back before subsequent dicing, bonding and packaging to reduce the package mounting height, reduce the chip package volume, improve the chip's thermal diffusion efficiency, electrical performance, mechanical properties and reduce the amount of dicing. Back grinding has the advantages of high efficiency and low cost. It has replaced traditional wet etching and ion etching processes to become the most important back thinning technology.

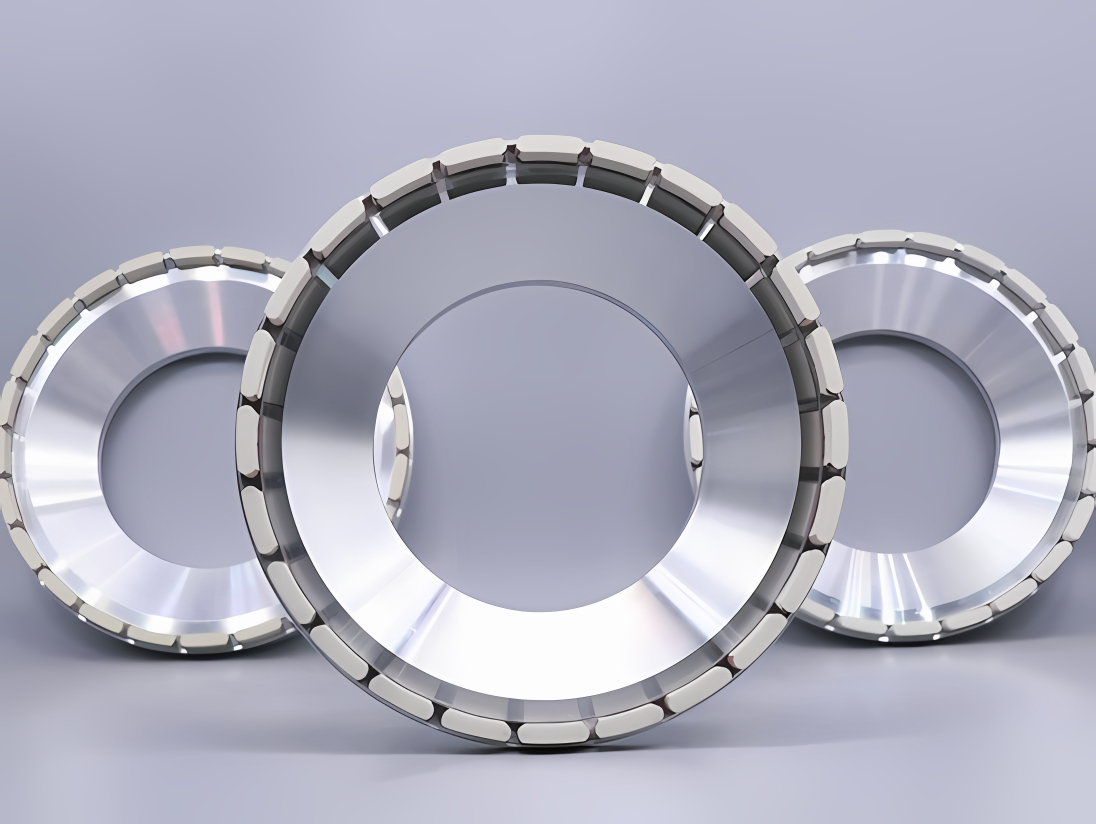

Diamond back grinding wheels are used for silicon wafer grinding. our advanced technology makes back grinding wheel possible to grind all types of semiconductor wafers with less subsurface damage.

The Role of Wafer Back Grinding in Semiconductor Manufacturing

Wafer back grinding is primarily performed to:

Reduce wafer thickness – Essential for high-performance applications like smartphones, tablets, and IoT devices.

Enhance heat dissipation – Thinner wafers improve thermal management, reducing overheating issues.

Improve mechanical flexibility – Critical for flexible electronics and advanced packaging.

Enable multi-layer stacking – Key for 3D IC integration and chip-scale packaging (CSP).

Common Wafer Back Grinding Methods

The wafer thinning process typically involves the following techniques:

Conventional Mechanical Grinding – Uses a diamond grinding wheel to thin the wafer efficiently while maintaining a smooth surface.

Chemical-Mechanical Polishing (CMP) – A combination of chemical etching and abrasive polishing to achieve ultra-flat surfaces.

Dry Plasma Etching – A non-contact method that provides precise control over wafer thinning with minimal damage.

RUIZUAN uses a diamond back grinding wheel made of vitrified bond, which is specially used for wafer thinning. vitrified diamond back grinding wheel covers a variety of grain sizes such as 600#, 800#, 1000#, 2000#, 8000#, etc., which can meet the processing needs of different customers. At the same time, the company also has the technical ability to produce 20000#~30000# grinding wheels, and can produce particles ranging from 600#-30000#, which provides the possibility for more sophisticated processing.

In addition, for thinning grinding wheels, RUIZUAN brand back grinding wheel replaces imported Japanese Sumitomo grinding wheels and has been supplying rough and fine grinding thinning grinding wheels to domestic and foreign customers stably:

1. Silicon wafer thinning back grinding wheel

400# 800# 1500# 2000# 6000# 8000# 10000# 15000#

2. Silicon carbide back grinding wheel

400# 800# 1500# 2000# 8000# 15000# 30000# (mostly imported grinding wheels)

3. Plastic back grinding wheel

400# 600# 800# 1000# 1200# 1500# 1800# 2000# 4000#

4. Quartz glass back grinding wheel

600# 800# 2000# 3000# 5000# 8000# 15000#

Post time: Feb-11-2025