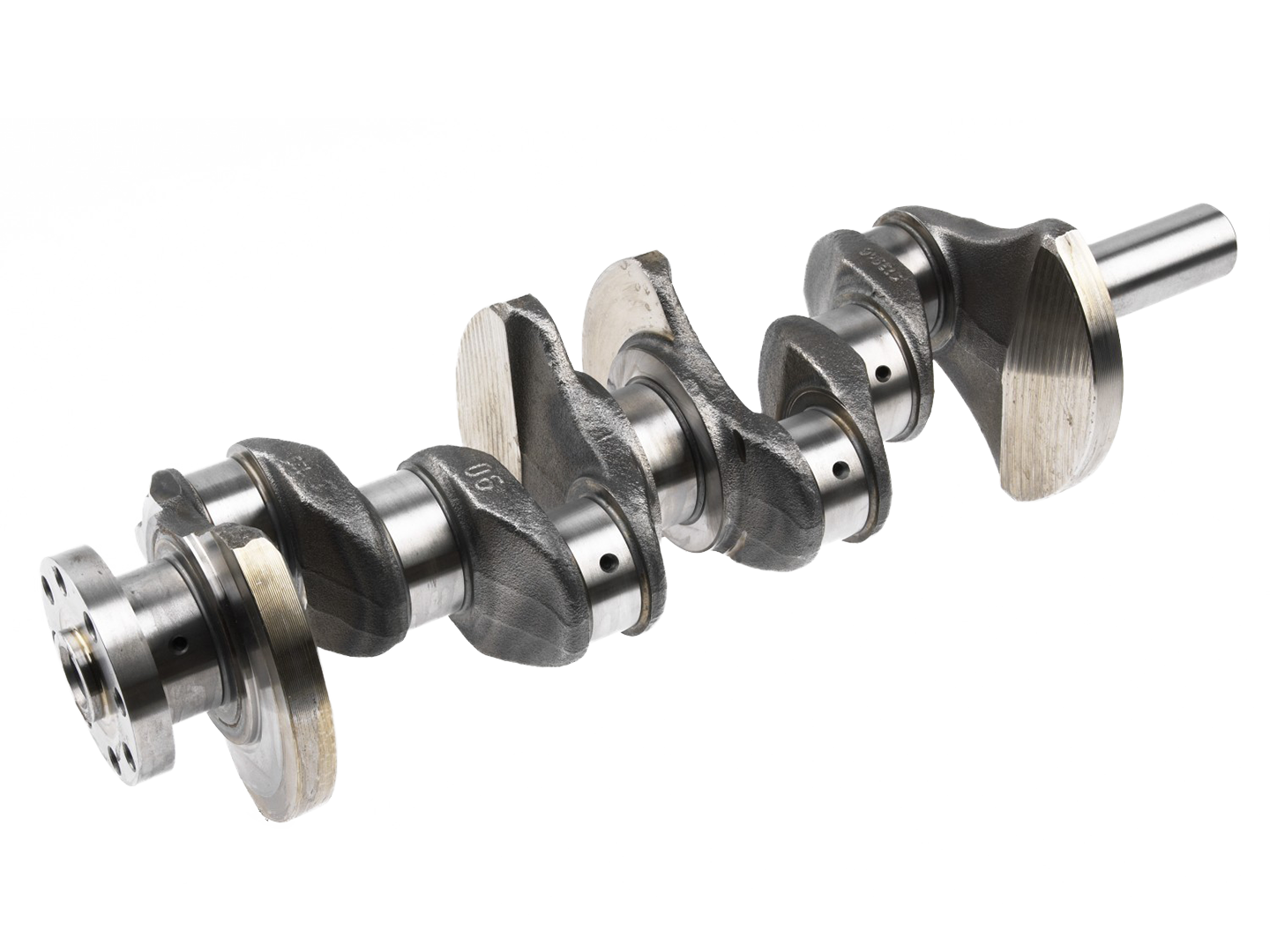

Understanding the Crankshaft's Role

The crankshaft is a fundamental component of an engine, playing a crucial role in converting the linear motion of the pistons into rotational motion. This conversion is essential for powering the vehicle or machinery.

The crankshaft's importance for smooth operation cannot be overstated. It acts as the heart of the engine, ensuring that power is transmitted efficiently and reliably. Without a properly functioning crankshaft, the engine would not be able to generate the necessary power to propel a vehicle or operate machinery.

In a typical internal combustion engine, the pistons move up and down in the cylinders. As the pistons move, they push and pull on the connecting rods, which are attached to the crankshaft. The crankshaft then converts this linear motion into rotational motion, which is used to drive the wheels of a vehicle or power other mechanical components.

For example, in a car engine, the crankshaft is connected to the transmission through a clutch or torque converter. The rotational motion of the crankshaft is transferred to the wheels through the transmission, allowing the car to move.

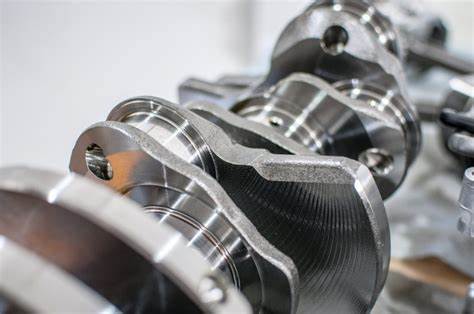

The Need for Dressing and Grinding

1.Improving Performance

Dressing and grinding play a crucial role in enhancing the crankshaft's performance. The process of grinding helps to ensure a proper fit between the crankshaft and other engine components. For example, a precisely ground crankshaft can reduce clearance between the bearings and the shaft, minimizing vibrations and noise. This results in a smoother operation and improved power transfer. According to industry data, a well-ground crankshaft can increase engine efficiency by up to 10%.

Reducing friction is another key benefit of dressing and grinding. A smooth surface on the crankshaft reduces the resistance between moving parts, allowing the engine to run more efficiently. This not only improves fuel economy but also reduces wear and tear on the engine. Grinding can remove imperfections and burrs on the surface of the crankshaft, resulting in a lower coefficient of friction.

2.Extending Lifespan

These processes can significantly prolong the life of the crankshaft. Over time, the crankshaft is subjected to wear and damage due to constant friction and stress. Dressing and grinding can address these issues by removing damaged layers and restoring the surface to its original condition. By doing so, it prevents further deterioration and extends the lifespan of the component.

For instance, if a crankshaft has developed surface cracks or scoring, grinding can remove the damaged area and provide a smooth surface for continued operation. Additionally, regular dressing and grinding can help detect potential problems early on, allowing for timely repairs and preventing catastrophic failures. According to some estimates, proper maintenance through dressing and grinding can double the lifespan of a crankshaft.

3.Maintaining Engine Efficiency

Dressing and grinding are essential for maintaining engine efficiency. An optimally functioning crankshaft is crucial for the efficient operation of the entire engine. When the crankshaft is not properly maintained, it can lead to decreased power output, increased fuel consumption, and reduced engine performance.

By ensuring a smooth surface and proper fit, dressing and grinding help to minimize friction and energy losses. This allows the engine to operate at its peak efficiency, reducing fuel consumption and emissions. Moreover, a well-maintained crankshaft can improve the overall reliability and durability of the engine, reducing the need for frequent repairs and downtime.

In conclusion, crankshaft dressing and grinding are indispensable for ensuring the optimal performance, longevity, and efficiency of engines. Whether in vehicles or machinery, these processes are vital for reliable operation and should be carried out regularly to maximize the benefits.

Post time: Oct-24-2024