Centerless grinding is a crucial process in the manufacturing industry, offering unique benefits for precision part production. Unlike traditional grinding methods that require centers or fixtures to hold the workpiece, centerless grinding provides a streamlined and highly efficient approach. Here, we will explore the fundamental principles that make centerless grinding an indispensable tool for achieving high precision and quality in cylindrical parts.

What is Centerless Grinding?

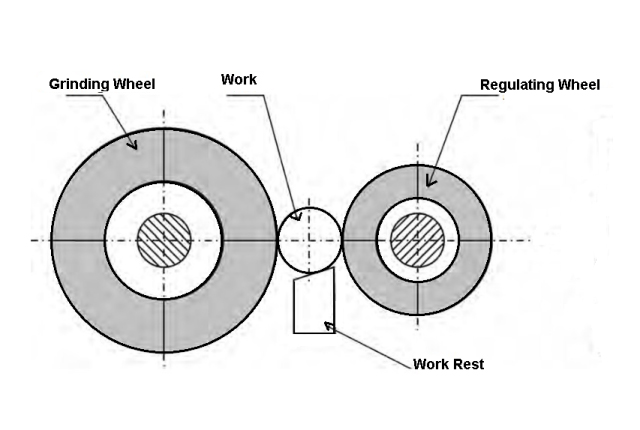

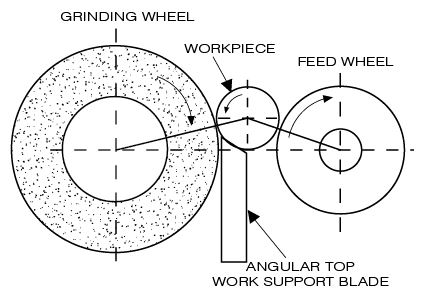

Centerless grinding is a machining process where the workpiece is supported between two rotating wheels—a grinding wheel and a regulating wheel—without the need for a spindle or fixture. This method is highly effective for producing uniform, round parts at high speeds.

The Working Principle

The core of centerless grinding lies in the interaction between the grinding wheel and the regulating wheel:

Grinding Wheel: The primary wheel responsible for material removal, rotating at high speeds.

Regulating Wheel: A secondary wheel that rotates at a slower speed, guiding and controlling the rotational speed and feed of the workpiece.

Work Rest Blade: Positioned between the two wheels, it supports the workpiece and helps maintain its position.

As the workpiece rotates and moves between these two wheels, the grinding wheel shapes and polishes it, while the regulating wheel ensures consistent feed and precise control.

Applications of Centerless Grinding

Centerless grinding is used across various industries, including automotive, aerospace, and medical device manufacturing. Common applications include:

Precision shafts and rods

Hydraulic components

Small cylindrical parts for mechanical systems

Why Choose Centerless Grinding?

Manufacturers benefit from centerless grinding due to its ability to maintain consistent quality and high throughput. The elimination of fixtures and the continuous process flow reduce setup time and cost, making it a preferred choice for many production lines.

Optimize Your Manufacturing with Centerless Grinding

Understanding the working principle of centerless grinding can significantly improve your operation’s efficiency and output quality. Investing in the right machinery and knowledge of process parameters will ensure superior results for all your precision grinding needs.

Post time: Nov-18-2024