Diamond grinding wheels are essential tools in precision grinding applications, known for their superior hardness and longevity. However, over time, they can become loaded with debris or lose their cutting efficiency, requiring proper dressing to restore their performance. In this article, we will discuss the importance of dressing a diamond grinding wheel, the methods used, and best practices to ensure optimal grinding results.

Why Dressing is Necessary

Dressing a diamond grinding wheel is crucial for several reasons:

Restores Cutting Efficiency: Over time, the wheel can become clogged with workpiece material, reducing its abrasive effectiveness.

Maintains Precision: Dressing helps maintain the wheel's shape and ensures accuracy in grinding operations.

Enhances Surface Finish: Properly dressed wheels result in smoother finishes and consistent results.

Extends Wheel Life: Regular dressing helps prevent excessive wear, maximizing the wheel's lifespan.

Dressing method for diamond grinding wheel

Diamond grinding wheels can be dressed using various methods to improve their performance and life. Based on the provided web results, common diamond wheel dressing techniques include:

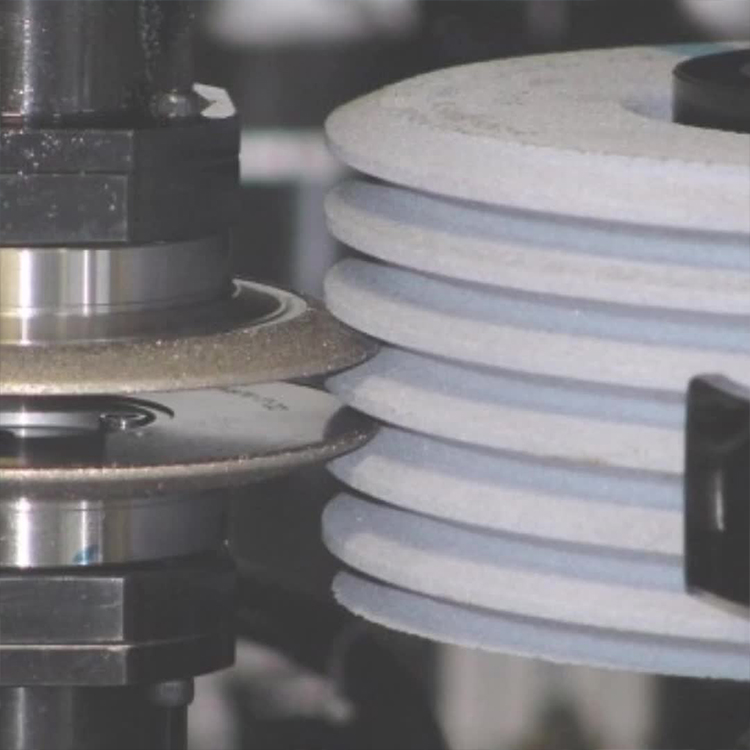

1 diamond roller dresser dressing using rotating cylindrical diamond dressers.

2 Diamond stick dressing using straight diamond rods that are fed across the wheel surface.

3 Electrochemical dressing using an electrolyte solution and electric current to remove wheel .material

4 Laser dressing using a focused laser beam to evaporate and reshape the abrasive grains.

There are a few steps for dressing a diamond grinding wheel:

Mount the diamond wheel securely on the grinding machine. Ensure the wheel is balanced and runs true.

Turn on the grinding machine and adjust the speed to the recommended dressing speed for the wheel. Typically around 3500-5000 rpm.

Apply the dresser to the wheel surface. Dressers can be diamond roller dresser, sticks or plates.

Move the dresser across the wheel in a continuous motion. Apply light to moderate pressure. The aim is to remove the worn surface and expose fresh abrasive grains.

Check the wheel for a smooth surface and consistent exposure of grains. Redress as needed.

You will need to continue dressing the wheel periodically to maintain grinding performance during use. The dressing interval depends on factors like the material being ground and wheel wear.

Dressing diamond grinding wheels is an essential maintenance practice that ensures optimal performance, precision, and longevity. By understanding the importance of dressing, selecting the right method, and following best practices, manufacturers can achieve high-quality grinding results and extend the life of their diamond wheels.

For high-quality diamond grinding wheels and professional dressing solutions, visit our website or contact us today!

Post time: Jan-25-2025