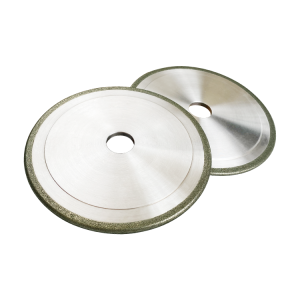

Choosing the correct hardness for diamond grinding wheels is crucial for achieving optimal performance and longevity in your grinding applications. At Zhengzhou Ruizuan Diamond Tools Co., Ltd., we understand the importance of selecting the right tool for the job. This guide will help you make an informed decision on the hardness of diamond grinding wheels suitable for your specific needs.

Understanding Diamond Grinding Wheel Hardness

The hardness of a diamond grinding wheel refers to the strength of the bond that holds the diamond particles in place. It determines how easily the diamond grains are exposed and worn away during the grinding process. The hardness scale for diamond grinding wheels typically ranges from soft to hard.

Factors to Consider When Choosing Hardness

Material to be Ground:

Hard Materials: For materials such as carbide, ceramics, and hard metals, a softer bond is recommended. A softer bond allows for faster exposure of new, sharp diamond particles, ensuring efficient cutting and reducing the risk of wheel glazing.

Soft Materials: For softer materials like aluminum, copper, and soft steels, a harder bond is preferable. A harder bond holds the diamond particles longer, providing a slower wear rate and extended wheel life.

Grinding Application:

Heavy Grinding: For heavy stock removal or rough grinding, a softer bond is ideal. It ensures that the wheel remains sharp and aggressive, preventing excessive heat buildup and maintaining cutting efficiency.

Finish Grinding: For fine finishing and polishing, a harder bond is suitable. It provides a finer surface finish and longer wheel life, as the diamond particles are worn away more slowly.

Grinding Machine Parameters:

Speed and Feed Rate: Higher grinding speeds and feed rates typically require a softer bond to prevent glazing and maintain cutting efficiency.

Coolant Use: The presence of coolant can affect the bond hardness selection. Coolant helps in reducing heat and friction, allowing the use of harder bonds in certain applications.

Wheel Shape and Size:

The shape and size of the grinding wheel also influence the choice of hardness. Larger wheels and those with complex shapes may benefit from a different bond hardness compared to smaller, simpler wheels.

General Guidelines for Hardness Selection

Soft Bond (Grade D-H): Ideal for hard, brittle materials and high-speed grinding applications.

Medium Bond (Grade I-L): Suitable for a wide range of general-purpose grinding tasks.

Hard Bond (Grade M-Z): Best for soft, ductile materials and low-speed grinding applications.

Consulting with Experts

Choosing the right diamond grinding wheel hardness can significantly impact your grinding efficiency and tool life. At Zhengzhou Ruizuan Diamond Tools Co., Ltd., our team of experts is always available to provide guidance and recommendations tailored to your specific requirements. We consider all the factors mentioned above to ensure you receive the most suitable grinding solution for your needs.

Selecting the appropriate hardness for your diamond grinding wheels is essential for achieving the best results in your grinding operations. By considering the material, application, machine parameters, and wheel characteristics, you can optimize performance and extend the life of your grinding tools. For personalized advice and high-quality diamond grinding wheels, contact Zhengzhou Ruizuan Diamond Tools Co., Ltd. today.

Post time: Jun-07-2024