In the precision-driven world of CNC machining, the choice of a grinding wheel can make or break your production quality and efficiency. Whether you're a seasoned manufacturer or just dipping your toes into the metalworking realm, understanding the nuances of selecting the right CNC grinding wheel is crucial. Here's your comprehensive guide.

Material Matters

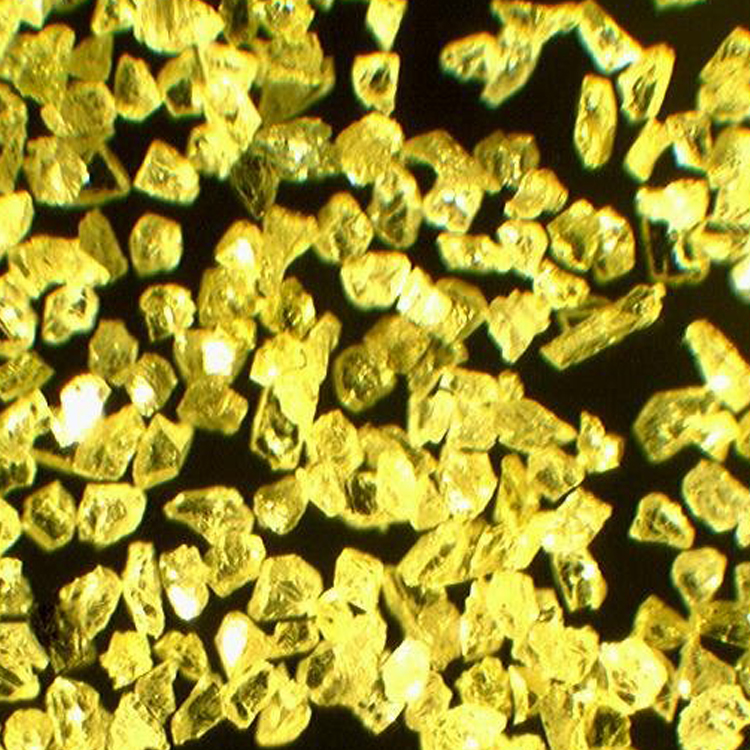

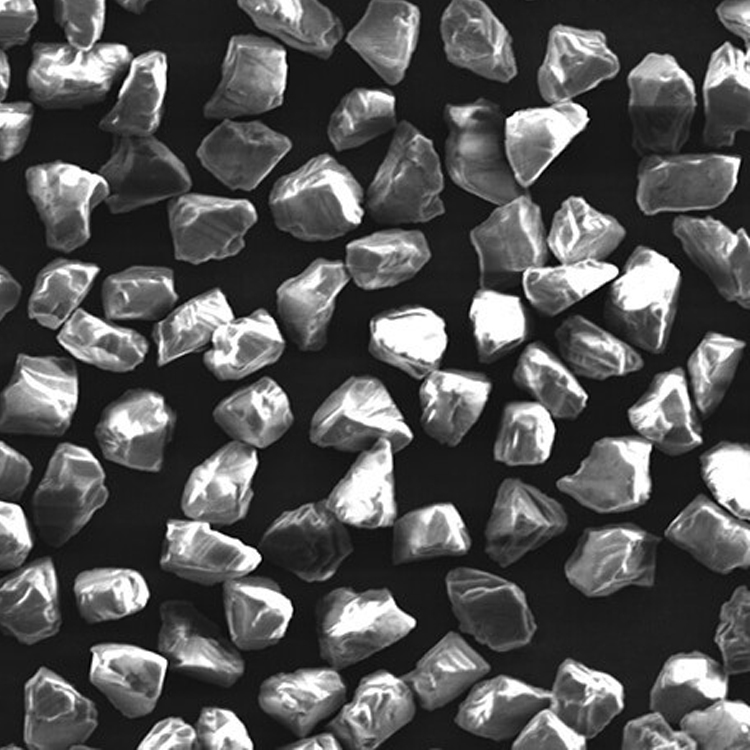

The workpiece material dictates the grinding wheel composition. For ferrous metals like steel, aluminum oxide wheels are a popular choice. Their high hardness and wear resistance ensure efficient material removal while maintaining a sharp cutting edge. When dealing with hardened steels or alloys, CBN (Cubic Boron Nitride) wheels step up. CBN can withstand extremely high temperatures, allowing for faster grinding speeds and finer finishes, crucial for industries demanding tight tolerances.

Diamond grinding wheels, on the other hand, are the go-to for non-ferrous materials such as ceramics, carbide, and gemstones. Their extreme hardness enables precise shaping and grinding without excessive wear, guaranteeing longevity and consistent performance.

Application range of CNC grinding wheel

CNC grinding wheel is suitable for grinding a variety of CNC tools (rotary tools), including:

-Carbide cutting tools (tungsten steel): These tools are often used to cut high-hardness materials such as cast iron, steel, etc.

-High-speed steel cutting tools: Suitable for processing medium-hardness materials, with good toughness and wear resistance.

-Stainless steel cutting tools: Used for processing difficult-to-process materials such as stainless steel, requiring the grinding wheel to have high wear resistance and thermal stability.

-End mill cutters and reamers: These tools are often used for forming and finishing in mechanical processing, requiring the grinding wheel to have good shape retention and surface quality.

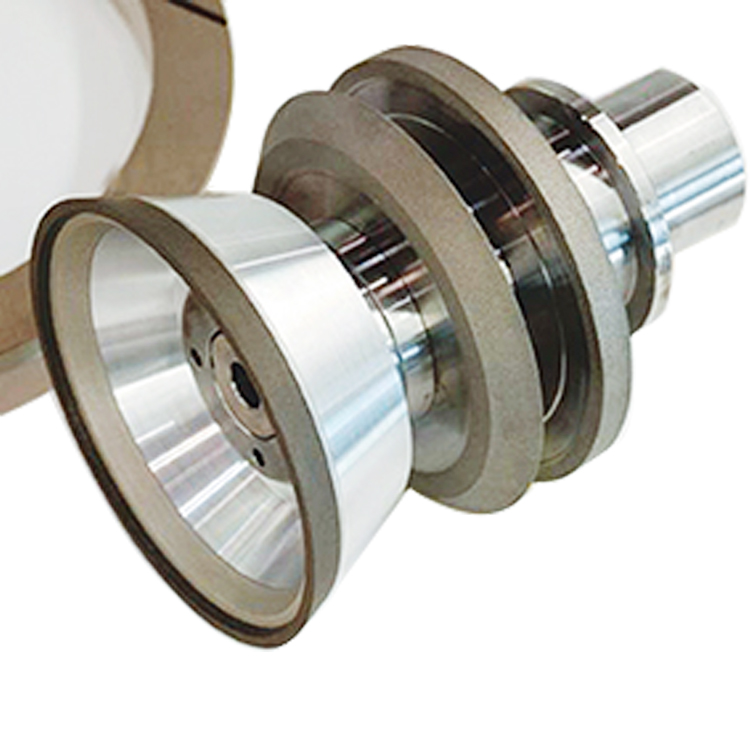

Applications of resin diamond CNC grinding wheel

resin diamond CNC grinding wheel is used for grooving, relief grinding, peripheral and end gear grinding of CNC tools such as solid carbide, high-speed steel drills, milling cutters and reamers.

Features of resin diamond wheel for CNC cutting tools:

(1) Suitable for high-efficiency grinding with fast feed.

(2) Good wear resistance and shape retention.

(3)Good self-sharpening, less grinding heat, reduced workpiece burns, and met the high-precision requirements of the tool.

(4) No clogging, easy to dress, extended dressing cycle, and reduced processing costs.

(5) The quality of the grinding workpiece edge is consistent and the finish is high, which makes the quality stable when processing downstream products.

Post time: Dec-09-2024