Dressing grinding wheels play an essential role in maintaining the sharpness and precision of other grinding wheels. They remove debris, reshape the wheel, and expose fresh abrasive grains, which enhance performance. Choosing the right dressing grinding wheel depends on several factors, including the material being worked on, the grinding wheel type, and the desired surface finish.

Consider the Type of Grinding Wheel

Different grinding wheels require specific dressing tools to maintain their effectiveness. For example, vitrified wheels may require diamond dressing tools to reshape and clean them effectively. Depending on the wheel's material and structure, certain dressing wheels will deliver better performance.

Material Compatibility

The dressing tool should be compatible with the material of the workpiece. For instance, harder materials such as carbide and hardened steels may require diamond dressing wheels, while softer materials like aluminum may need different types of abrasives.

Frequency of Dressing

If your application requires frequent dressing due to heavy grinding, a more robust dressing wheel like a diamond wheel will provide longer tool life and reduce downtime. On the other hand, less frequent dressing may allow for a more economical option.

Surface Finish Requirements

Choosing the right dressing tool also depends on the desired surface finish. Finer grits and more precise dressing wheels produce a smoother finish, while coarser grits might be better suited for aggressive material removal.

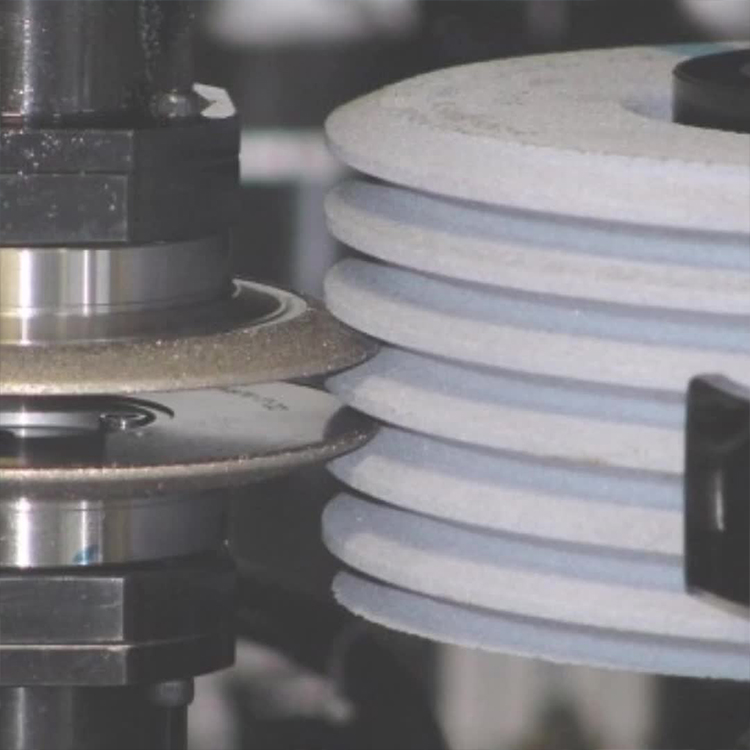

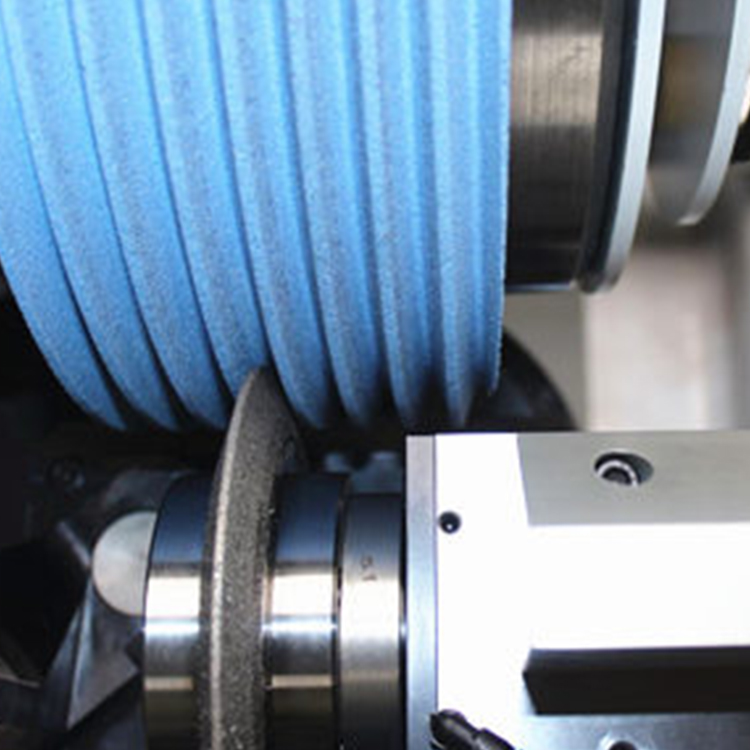

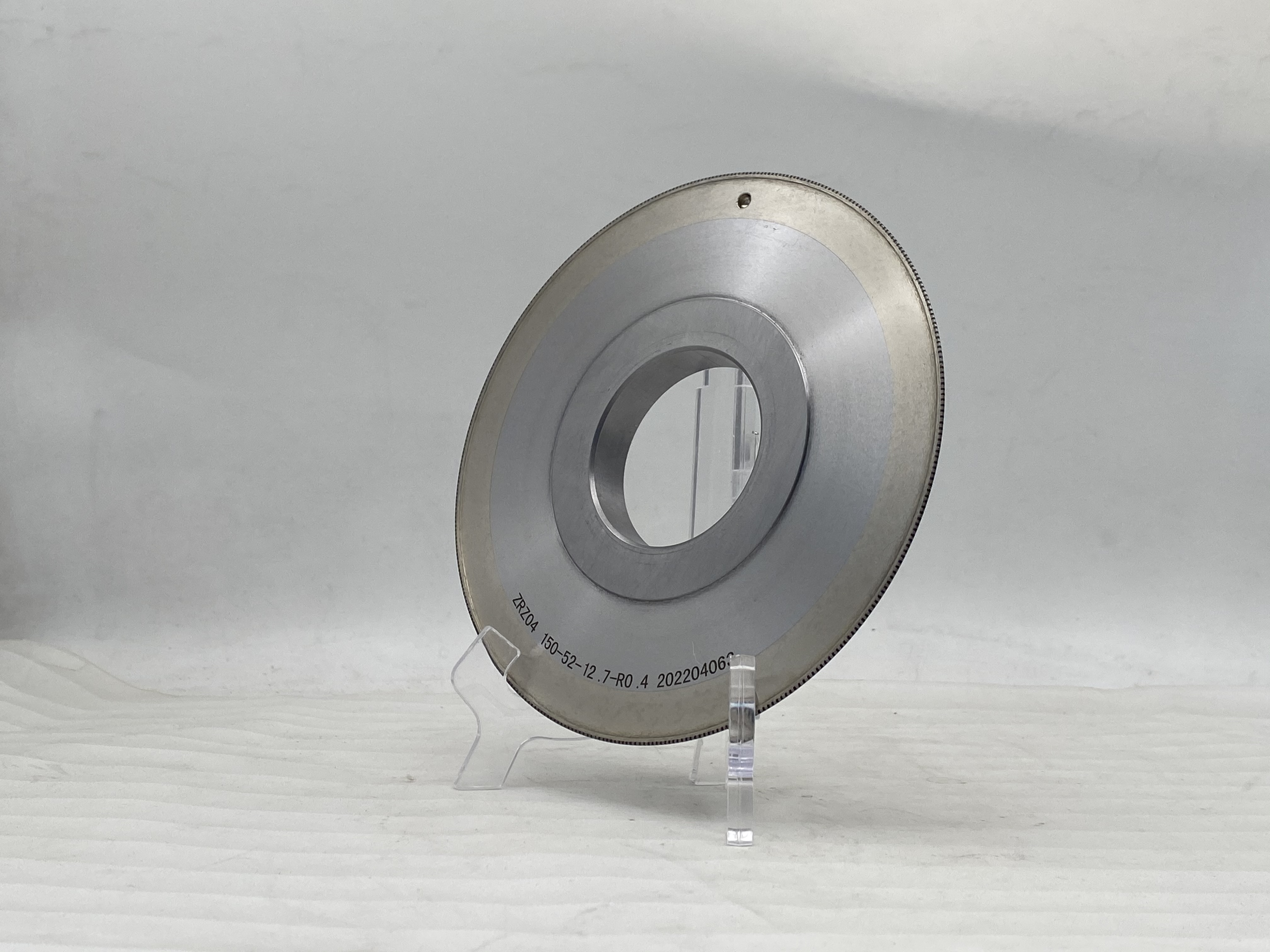

Diamond roller dresser is a newly developed dressing tool, which is easy to dress various complex forming surfaces, short dressing time, good surface precision, convenient dressing operation and so on. Its use effect has been gradually recognized by people, in production has also been more and more widely used.

In the case of obtaining the same roughness value requirements, it should be used as far as possible to avoid accelerated roller wear due to high relative speed. However, the workpiece burns and the low yield of grinding are closely related to the particle size of diamond roller, and the selection of diamond particle size must meet the requirements of workpiece smoothness and dimensional accuracy.

Post time: Sep-20-2024