What is diamond roller?

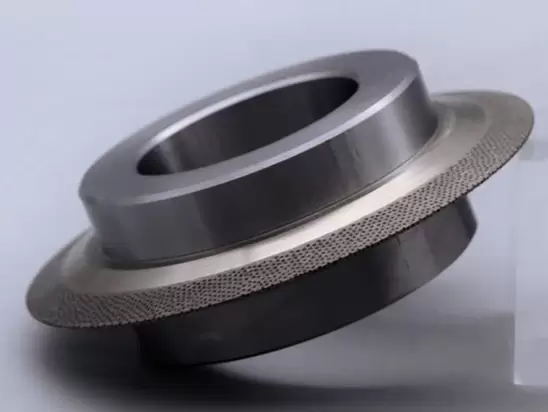

The diamond roller is a high-efficiency, high-life, low-cost grinding wheel dressing tool that uses electroplating or powder metallurgy to embed a large number of diamond particles on the surface of a steel roller. It is used for special machine tools and gear grinders for large-scale forming grinding.

There are three types of diamond rollers: sintered diamond rollers, electroplated diamond rollers and CVD diamond rollers. Each type of diamond roller has different advantages and disadvantages, and the application industry is also different.

Sintering method: divided into hand-planted sintered rollers and randomly distributed sintered rollers, with strong durability;

Electroplating method: high-precision production of small and complex rollers;

CVD roller: good dressing effect on CBN grinding wheels.

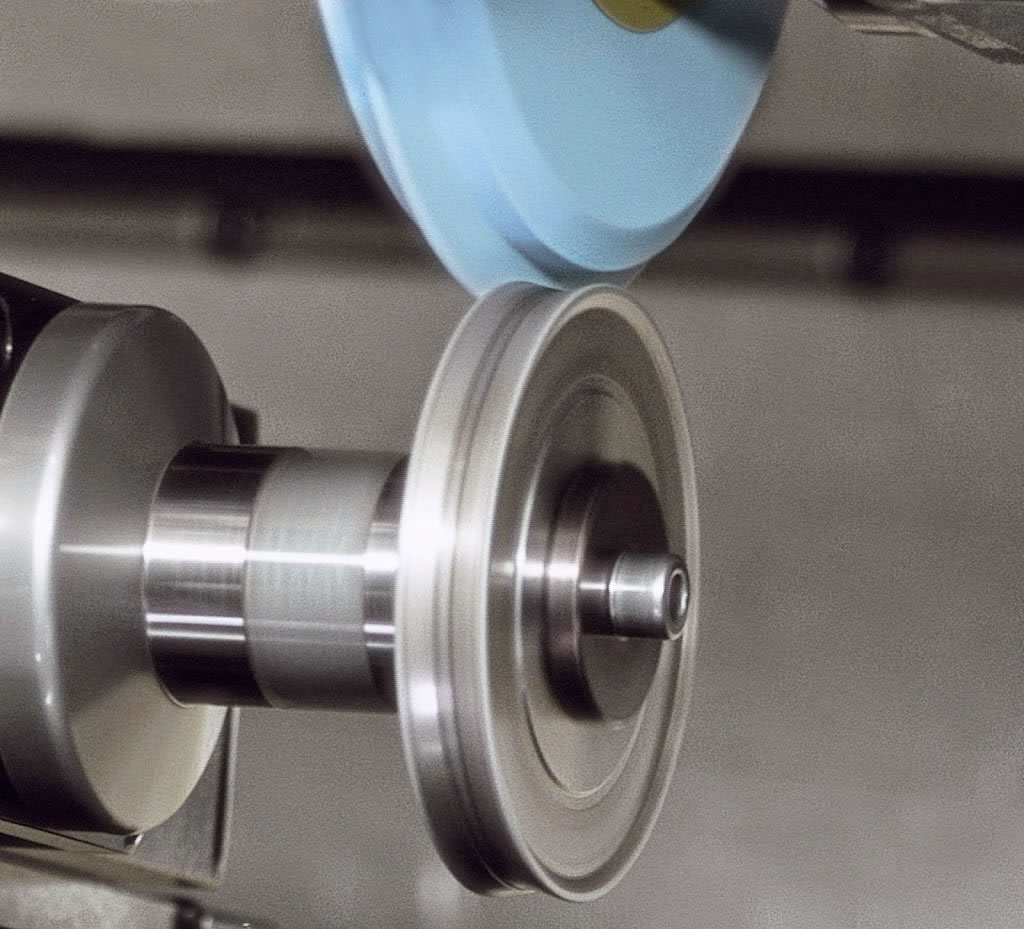

According to different application scenario requirements, diamond roller dressing processes are divided into two types: cut-in diamond roller dressing and pendulum diamond roller dressing. Because cut-in diamond roller dressing is simpler than pendulum diamond roller dressing, it is more widely used in actual production.

Among the choices of high-precision gear processing methods, grinding to achieve the target accuracy is currently a relatively wide choice. In the grinding process, the grinding wheel itself often causes deviations in gear accuracy. At this time, the importance of dressing tools is highlighted. Diamond dressing rollers are indispensable precision tools in gear grinding. They ensure the shape and accuracy of the grinding process by maintaining the best condition of the grinding wheel.

Features of diamond dressing rollers

High hardness and wear resistance

As the hardest material in nature, the hardness and wear resistance of diamond enable diamond dressing rollers to maintain a stable dressing effect for a long time and still perform well under high load and high temperature conditions.

High-precision machining

Diamond dressing rollers usually have a high-precision manufacturing process, which can provide a detailed dressing effect and ensure the accuracy and consistency of the grinding wheel.

Application areas

Diamond dressing rollers are widely used in automotive, aerospace, mold manufacturing, and other fields, especially in occasions where high-precision gear machining is required.

Post time: Nov-07-2024