The type of material being ground plays a significant role in the wear rate of a grinding wheel. Harder materials like carbide, stainless steel, and ceramics require more abrasive power, which can accelerate wheel wear. Conversely, softer materials like aluminum or plastics cause less wear. Selecting the correct wheel for each specific material is essential for extending its lifespan.

The lifespan of a grinding wheel is a critical consideration in any industrial or manufacturing operation. As the grinding wheel wears down, its performance diminishes, leading to increased costs and production delays. Understanding the factors that impact the lifespan of a grinding wheel can help businesses make informed decisions, optimize tool usage, and reduce operational costs. Below are the key factors influencing the longevity of grinding wheels and how to maximize their lifespan.

Material Being Worked On

Grinding Speed and Feed Rate

Excessive grinding speed and improper feed rates can lead to excessive friction, heat, and wear on the grinding wheel. Overworking the wheel by pushing it beyond its optimal operating parameters shortens its lifespan. To maintain efficiency, it's crucial to use recommended speeds and feeds for both the grinding wheel and the material being processed.

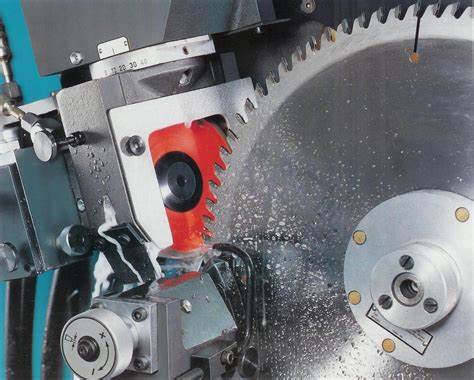

Coolant Use

The use of coolant during the grinding process can significantly prolong the life of a grinding wheel. Coolants help reduce heat buildup, prevent thermal damage, and remove grinding debris, thus improving wheel performance. Lack of proper coolant usage can cause overheating, rapid wear, and a reduction in wheel life.

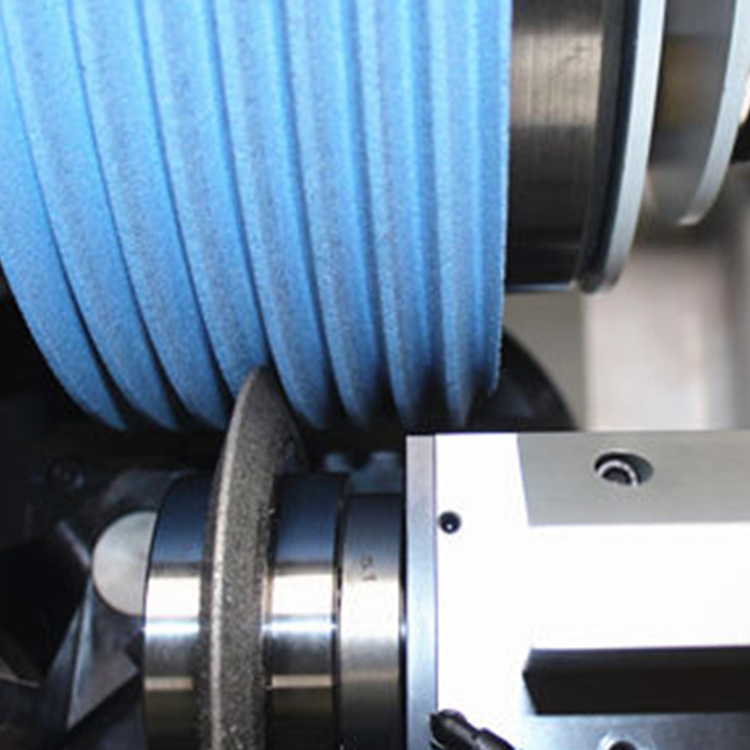

Wheel Dressing

Regular dressing is essential for maintaining the wheel's cutting performance and extending its lifespan. Over time, grinding wheels become loaded with debris and lose their sharpness. Diamond dressing tools are commonly used to restore the wheel's original shape and remove embedded material. Proper dressing ensures smoother operation and better results.

Optimizing the lifespan of grinding wheels depends on a variety of factors, from the materials and processes involved to the care and maintenance of both the wheel and the machinery. By paying close attention to the material composition, operating conditions, and regular maintenance, businesses can reduce costs and increase productivity. At Zhengzhou Ruizuan Diamond Tool Co., Ltd., we offer a range of high-quality diamond and CBN grinding wheels designed to deliver long-lasting performance in even the most demanding applications.

Post time: Oct-11-2024