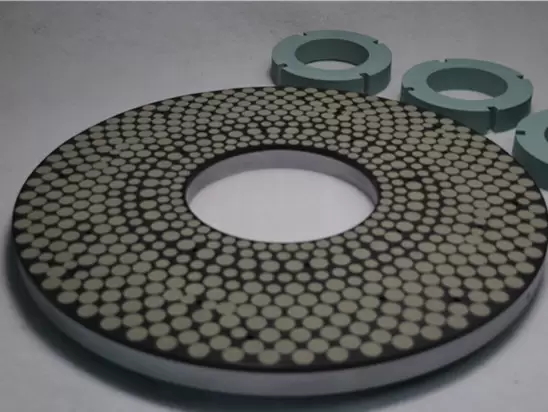

At Zhengzhou Ruizuan Diamond Tool Co., Ltd., we are dedicated to providing top-quality diamond tools for various industrial applications. One of our premier offerings is the double disc grinding wheel, renowned for its efficiency and precision. In this article, we will delve into the features, advantages, and applications of double disc grinding wheels, highlighting why they are a superior choice for many grinding tasks.

1. High Efficiency

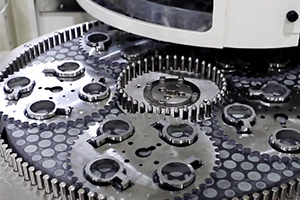

Double disc grinding wheels enable the simultaneous grinding of two sides of a material, significantly enhancing the grinding process's efficiency. This dual action reduces grinding time and increases productivity, making it ideal for large-scale manufacturing environments.

2. Superior Accuracy and Surface Finish

These grinding wheels achieve exceptional flatness and parallelism, with tolerances as tight as ±0.0005 inches (0.0127 mm). This precision results in smoother and more consistent surface finishes, which are critical for applications requiring stringent quality standards.

3. Reduced Operational Costs

The efficient grinding process of double disc grinding wheels not only cuts down on machining time but also minimizes the wear and tear on the grinding wheels. This leads to fewer wheel replacements and lower maintenance costs, contributing to overall cost savings.

4. Enhanced Workpiece Quality

By grinding both sides of a workpiece simultaneously, double disc grinding ensures uniform material removal. This uniformity reduces the risk of thermal deformation and internal stresses, resulting in higher quality and more stable workpieces.

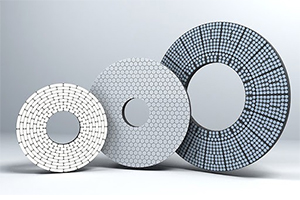

Double disc grinding wheels are versatile and can be used in various industries, including automotive, aerospace, and medical manufacturing. They are particularly effective for:

Precision Blanks: Grinding high-precision blanks for components such as gears, bearings, and valve plates.

Metal Components: Processing ferrous and non-ferrous metals, including stainless steel, tool steels, and high-strength alloys.

Sintered Metals and Ceramics: Achieving precise dimensions and surface finishes in sintered metals and ceramics.

Automotive Parts: Manufacturing critical automotive components like connecting rods and camshafts with tight tolerances.

Materials Processed with Double Disc Grinding Wheels

Double disc grinding wheels can handle a wide range of materials, including:

Metals: Stainless steel, tool steels, sintered metals, high-strength alloys, ferrous and non-ferrous metals.

Non-Metals: Ceramics and certain types of plastics, providing versatility for various industrial applications.

Double disc grinding wheels from Zhengzhou Ruizuan Diamond Tool Co., Ltd. offer unparalleled efficiency, precision, and cost-effectiveness. Their ability to process a variety of materials with high accuracy makes them an indispensable tool in modern manufacturing. For more information on our double disc grinding wheels and other diamond tools, please contact us or visit our website.

Post time: Jul-10-2024