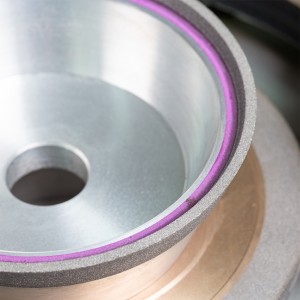

Metal bond grinding wheels are a crucial tool in the manufacturing industry, providing the precision and consistency needed for high-quality products. These wheels are designed with a rigid metal matrix that ensures stability and durability during the grinding process. The consistent abrasive performance of metal bond grinding wheels allows for precise material removal, resulting in superior surface finishes and dimensional accuracy.

Metal bond grinding wheels elevate precision by enabling microscopic control in forming. The rigid structure and consistent abrasive performance of these wheels allow for precise material removal at the microscopic level, ensuring that the desired shapes and dimensions are achieved with exceptional accuracy. This level of control is essential for meeting the stringent requirements of modern manufacturing processes.

Furthermore, metal bond grinding wheels contribute to reduced dimensional variations in the finished products. The precise material removal and microscopic control offered by these wheels result in minimal dimensional variations, ensuring that the final products meet the specified tolerances and requirements. This level of precision is crucial for industries where tight dimensional control is essential.

In conclusion, metal bond grinding wheels play a vital role in elevating precision in manufacturing processes. With their rigid metal matrix, consistent abrasive performance, and ability to enable microscopic control and reduce dimensional variations, these wheels are essential for achieving high-quality, precise results in various industries. Their contribution to precision and accuracy makes them a valuable tool for manufacturers seeking to deliver superior products to their customers.

Post time: Apr-02-2024