The diamond dicing blade is mainly composed of electroformed nickel-based bond, resin and metal bond. When dicing, the spindle drives the blade to rotate to achieve high rigidity, thereby removing material to achieve cutting.

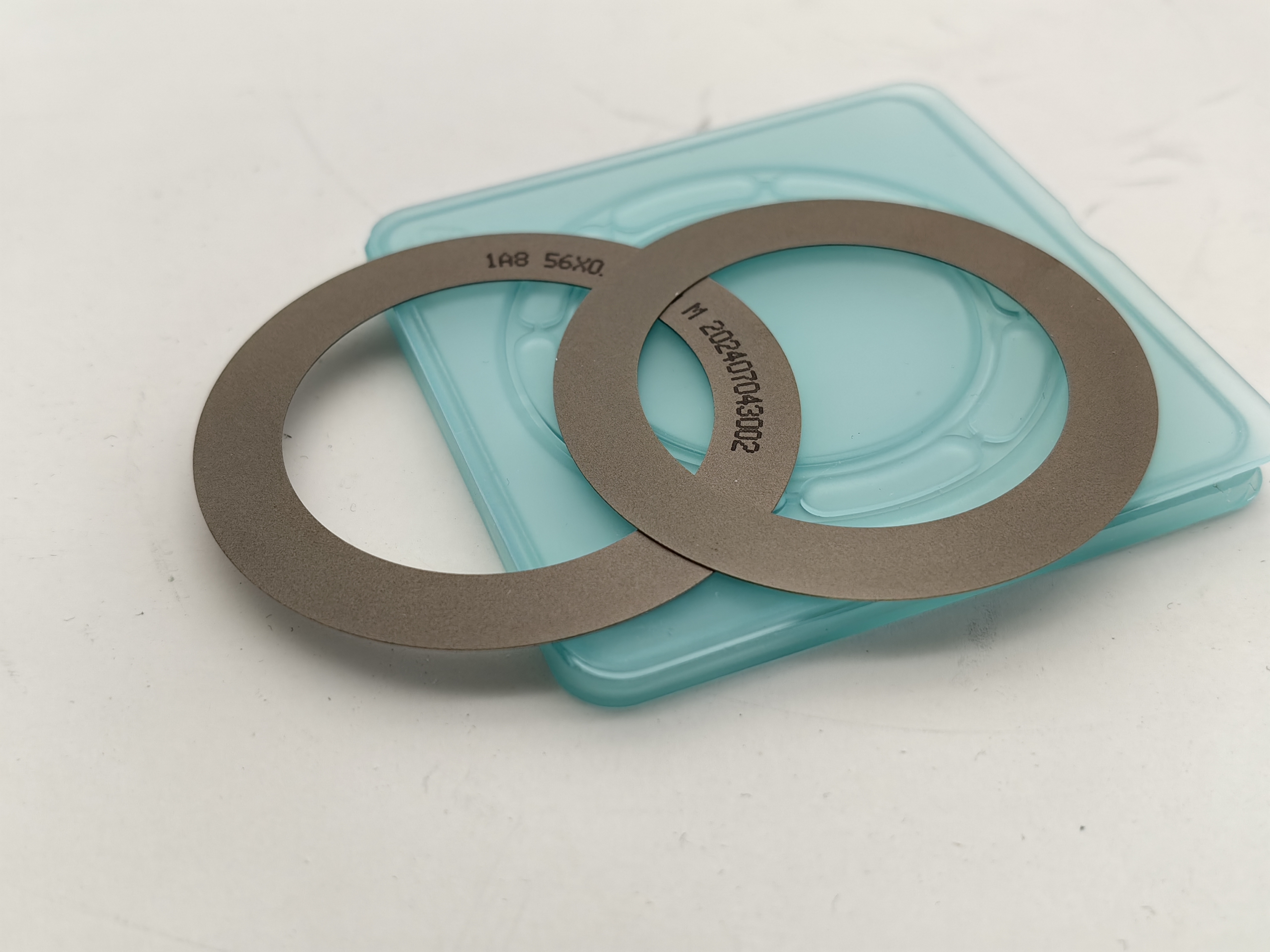

Diamond dicing blade is a high-precision cutting tool used in semiconductor manufacturing, electronics, and optical industries. It is designed to make fine, clean cuts on silicon wafers, ceramics, glass, sapphire, and composite materials. The blade consists of ultra-hard diamond abrasives bonded with different materials to achieve optimal performance based on the material being diced.

Types of Diamond Dicing Blades

Resin Bond Diamond Dicing Blade

Best suited for fragile and brittle materials such as semiconductor wafers, glass, and quartz.

Provides smooth cuts with minimal chipping, reducing material waste.

Offers excellent cooling and self-sharpening properties for extended tool life.

Application of resin diamond dicing blade:

Resin bonded diamond dicing blades can be used to cut quartz, glass, lithium niobate, crystals and other brittle and hard materials, IC packages (QFN, DFN), etc.

Metal Bond Diamond Dicing Blade

Ideal for hard and dense materials like ceramics, sapphire, and carbide.

Delivers high durability and long lifespan, ensuring cost-effectiveness in high-volume production.

Provides aggressive cutting performance, making it suitable for precision industrial applications.

Application of metal diamond dicing blade:

Metal bond diamond dicing blades can be used to process optical devices, ceramics, ferrite, quartz, IC packaging (BGA), optical communications (Faraday), etc.

The function of the bond in diamond tools is to firmly stick the diamond abrasives together. Bonding agents of different hardnesses have a greater impact on the life of the blade.

(1)The hubless diamond dicing blade can accelerate the “self-sharpening” of diamond particles, keep the dicing blade in a relatively sharp state, and reduce the problems of front chipping, delamination and burrs of the cutting material. The hard bond can better hold the diamond particles, increase the wear resistance of the blade, and extend the life of the blade.

(2)The disadvantage of the hubless diamond dicing blade is the shortened blade life, and the disadvantage of the hard bond is the poor quality of the cut product.

Post time: Feb-17-2025