The semiconductor industry demands unparalleled precision and efficiency, and diamond grinding wheels have emerged as essential tools to meet these stringent requirements. Known for their hardness, durability, and cutting efficiency, diamond grinding wheels are pivotal in achieving the fine tolerances and high surface quality required for semiconductor manufacturing.

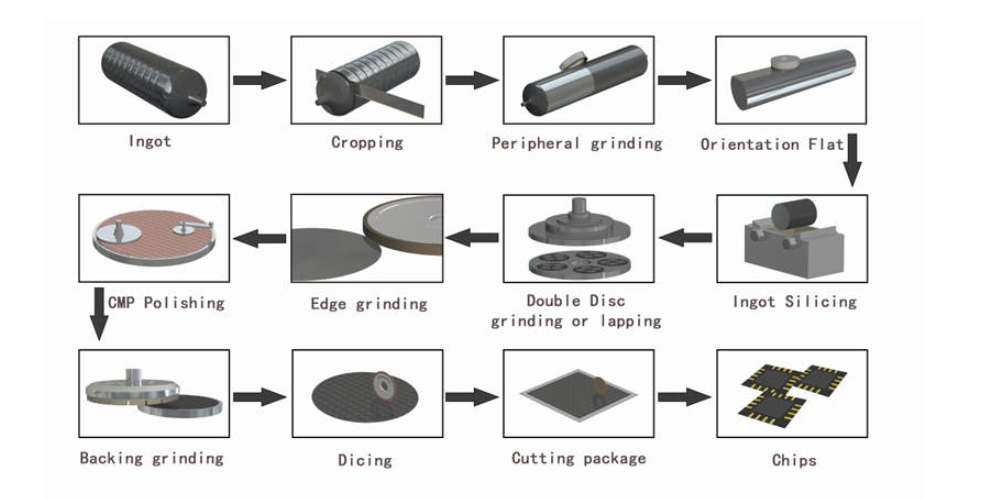

Manufacturing processes for silicon semiconductor

Silicon Ingot ⇒ Cropping(electroplated bandsaw) ⇒ Cylindrical / Flat Grinding Silicon Rod ⇒ Ingot Silicon (diamond wire) ⇒ Lapping (double side wheel/polishing pad) ⇒ Edge Grinding ⇒ Surface grinding ⇒ polishing⇒ wafer⇒ patterning ⇒ back grinding (vitrified / resin wheels) ⇒ dicing (dicing blades)⇒ chips ⇒ molding ⇒ packaging

Applications in Semiconductor Manufacturing

Wafer Back Grinding

Diamond grinding wheels are extensively used for thinning silicon wafers to the required thickness, ensuring a smooth and flat surface while maintaining structural integrity.

Edge Grinding

To ensure chip durability and reduce the risk of cracking during further processing, diamond wheels are employed for precise edge shaping and smoothing of wafers.

Polishing and Planarization

High-precision diamond grinding wheels are critical in achieving uniform wafer surfaces, ensuring that they meet the stringent specifications for electronic applications.

Dicing and Cutting

Diamond wheels enable clean and precise cutting of wafers into individual chips, reducing material wastage and ensuring high-quality outputs.

At Zhengzhou Ruizuan Diamond Tool Co., Ltd. , we specialize in providing high-quality diamond grinding wheels tailored to the specific needs of the semiconductor industry. Our products are engineered for precision, efficiency, and durability, ensuring optimal performance in every application.

Post time: Dec-20-2024