Products Description

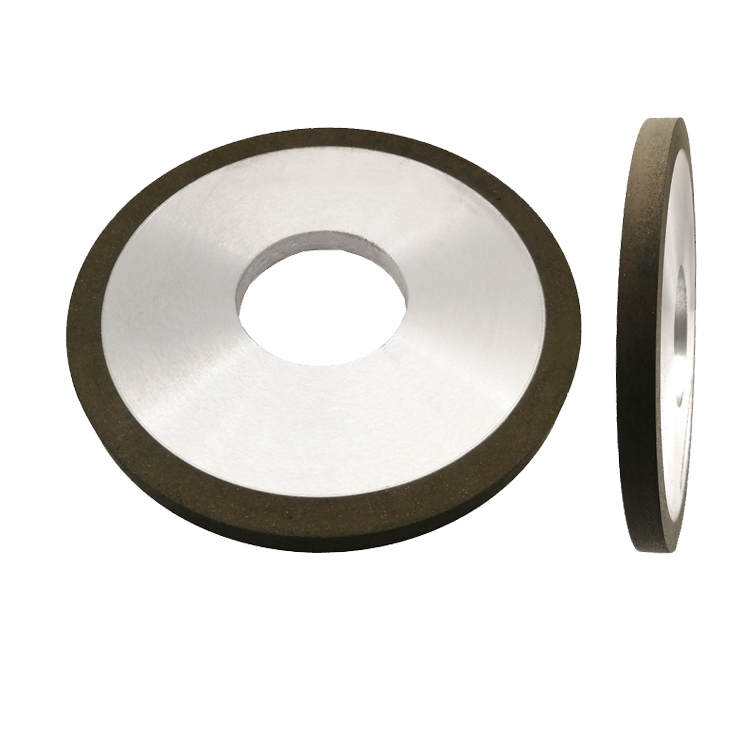

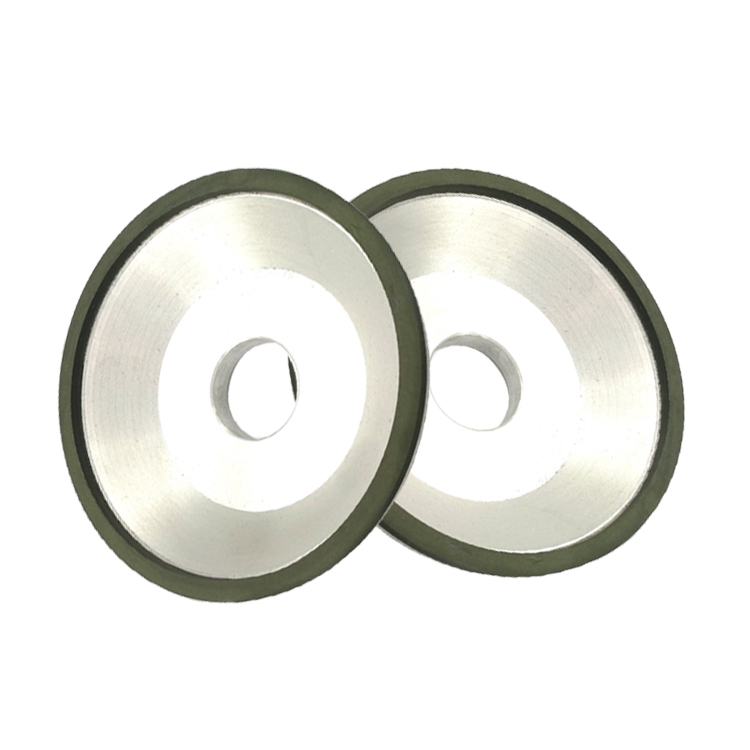

| Bond | Resin / Hybrid | Grinding Method | Sharpening Fluting Gashing Cylindrical Grinding |

| Wheel Shape | 1A1, 1V1, 11V9, 11A2, 12V9, 12A2, 1A1R | Workpiece | Metal cutting tools |

| Wheel Diameter | 75, 100, 125, 150, 200mm | Workpiece Materials | Tungsten Carbide HSS steel |

| Abrasive Type | SD, SDC, CBN | Industries | Metalworking Metal Cutting |

| Grit | 80/100/120/150/180/220/240/280/320/400 | Suitable Grinding machine | Tool Cutter Grinder |

| Concentration | 100, 125, 150 | Manual or CNC | Manual & CNC |

| Wet or Dry Grinding | Dry & Wet | Machine Brand | WalterStar Vollmer ISELLI |

Metalworking needs tools of milling, turning, boring, drilling, threading, cutting and grooving. These tools are usually made of High-Speed Steel, Tool Steel, Tungsten Carbide, Synthetic Diamond, Natural Diamond, PCD and PCBN.

All these materials aver very hard, above HRC30. So when when grind them, you usually need Diamond or CBN Grinding Wheels.

Features

1. High Profile Angle Retention Ability

2. Sharp & Fast Grinding

3. Excellent surface Finishes

4. Less Dressing

5. High Product

We designed series diamond and CBN grinding wheels for woodworking tools grinding and sharpening.

1.Solid Carbide / HSS tools grinding fluting gashing Diamond CBN wheels for CNC Grinder

2.Carbide HSS tool Sharpening Grinding Diamond CBN Wheels for Tool Cutter Grinder

3.Drill and Endmill sharpening Diamond CBN Wheels on Drill Endmill sharpener

FAQ

1. What are your prices?

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your company contact us for further information.

2.Do you have a minimum order quantity?

Yes, we require all international orders to have an ongoing minimum order quantity. If you are looking to resell but in much smaller quantities, we recommend you check out our website

3.Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

4.What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment. The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

5.What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal: 30% deposit in advance, 70% balance against the copy of B/L.

-

Diamond CBN Grinding Wheel Diamond Tools for Me...

-

12A2 Resin Diamond Grinding Wheel For Universal...

-

11A2 Resin Diamond Grinding Wheel For Universal...

-

1A1 Resin Diamond Wheel Surface Grinding For Mi...

-

Diamond CBN Grinding Wheel for CNC Tool Grinder

-

Metalworking 1V1 Resin Diamond Grinding Wheel f...