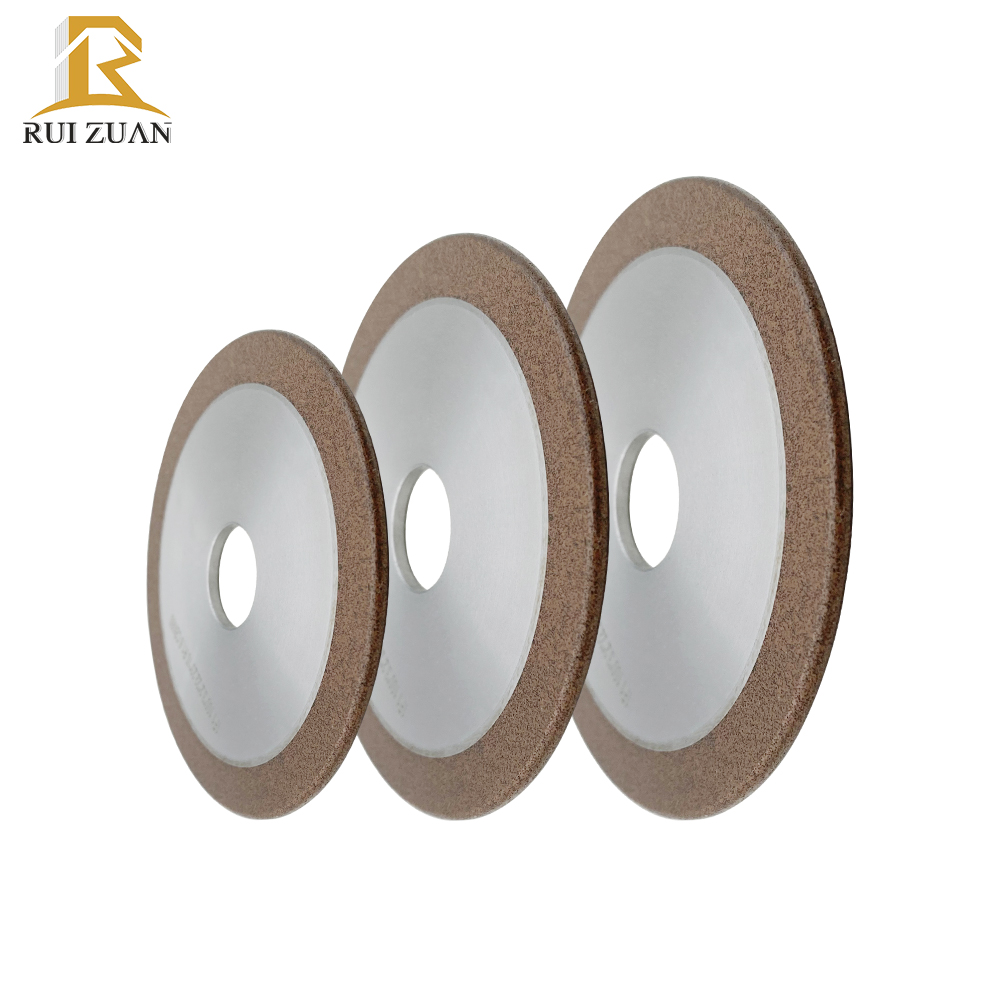

Grinding Wheels for Photovoltaic Industry

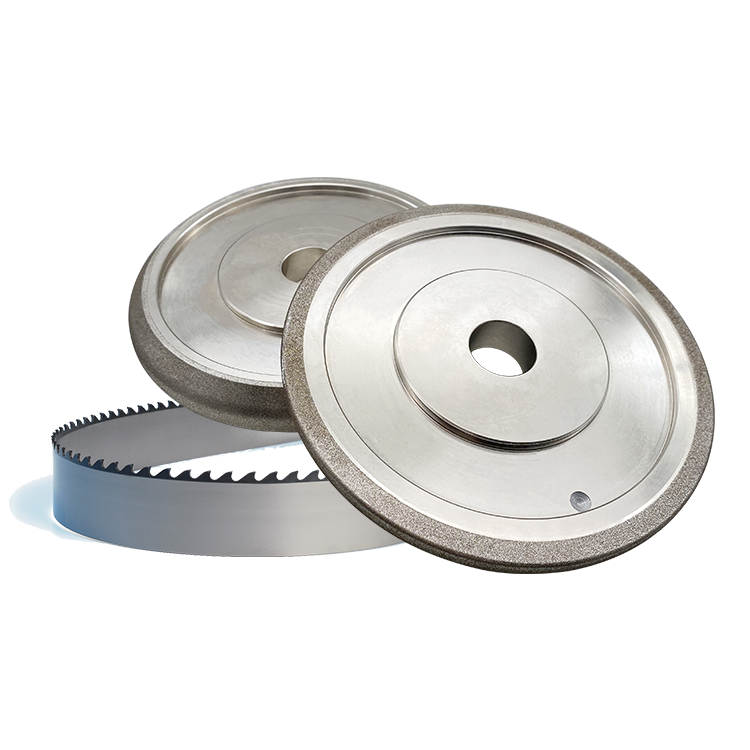

Grinding wheels used for silicon wafer thinning are typically made of diamond abrasive material. Diamond is an extremely hard material that is capable of effectively grinding and shaping silicon, which is also a hard material. The diamond abrasive particles are bonded together with a metal matrix, forming the grinding wheel.

|

|||||||||||||||||||||||||||||||||||||||||||

Features of cylindrical grinding wheel for silicon ingot

1.Realizes a total-like cost cut by fast material removal

2.Minimal influence on crystalline structure

3.Low grinding load, good grinding performance and wear resistance

4.Ingot surface with a high flat degree.

5.Low dressing frequency

Mainly used for flat grinding and chamfering of polycrystalline silicon; flat and cylindrical grinding monocrystalline silicon.

Grinding Objects: Sapphire wafers, silicon wafers, gallium arsenide, and gallium nitride wafers. Work Piece Materials: Synthetic sapphire, monocrystalline silicon, gallium arsenide and gallium nitride.