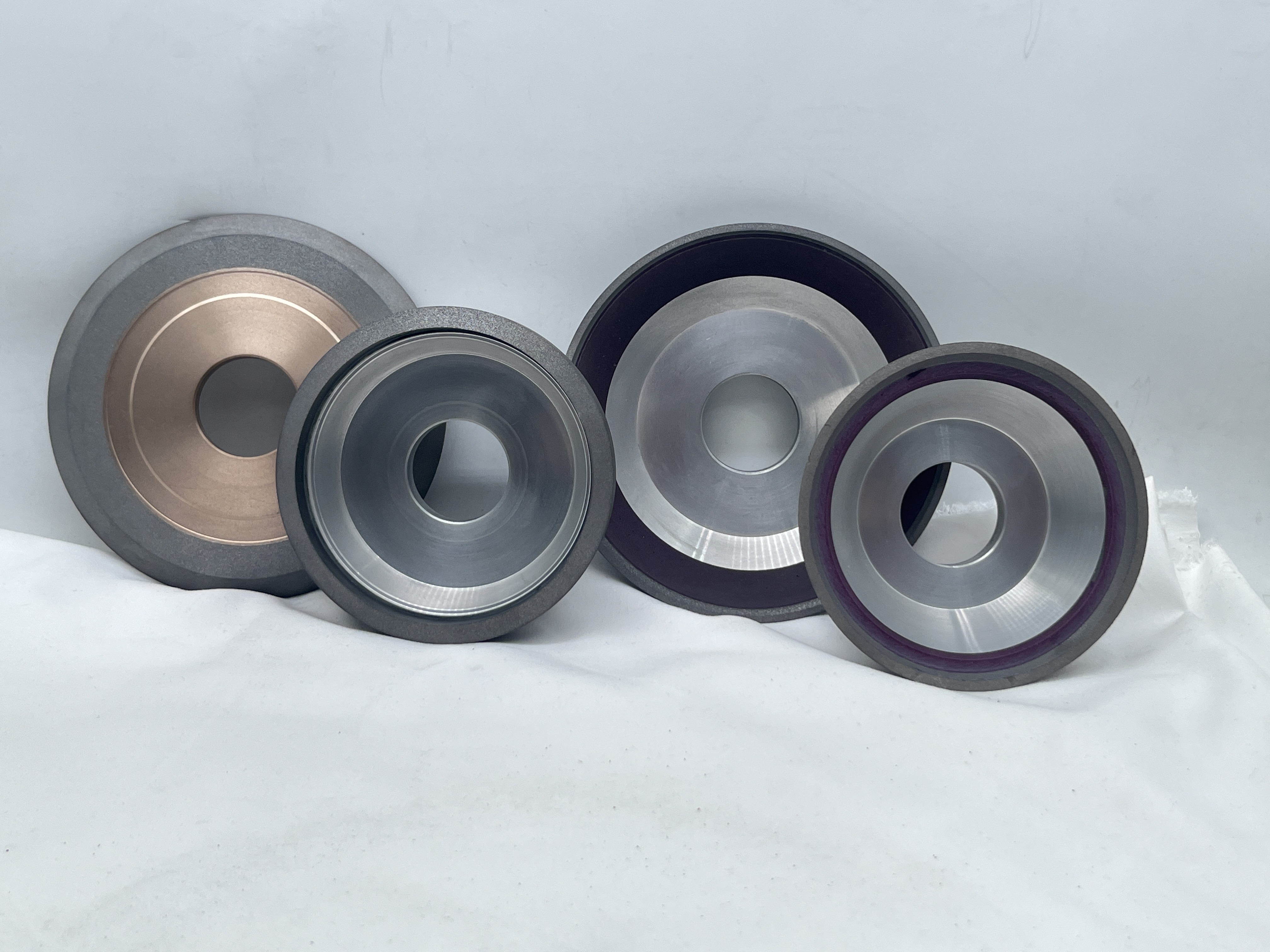

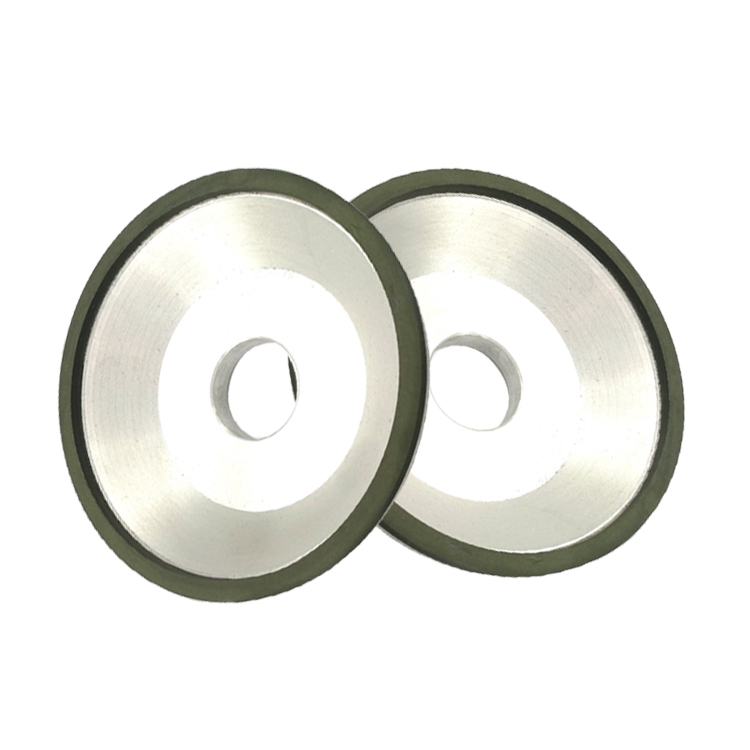

The whole new hybrid grinding wheel in combination of multiple bonding method is mainly utilized by CNC tooling grinding machine which engages to groove and grind powerfully for carbide endmill. It can be also used for grinding other tough and fragile materials as well as HSS and heat treatment materials.We have a wide choice of off-the-shelf products, with the possibility of custom-made and reprofiled wheels to enable complex geometries.

|

Metalworking tools needs of milling, turning, boring, drilling, threading,cutting and grooving. These tools are usually made of High-Speed Steel,Tool Steel,Tungsten Carbide,Synthetic Diamond,Natural Diamond,PCDand PCBN.All these materials are very hard, above HRC30. So when grind them, you usually need Diamond or CBN Grinding Wheels. Ruizuan designed resin bond and hybrid bond diamond cbn grinding wheels for sharpening them.

Advantages of grinding wheel on CNC machine

1.Low cutting forces

2.High material removal rates

3.Low machine power consumption

4.Low frictional heat

5.Smooth surface finish and edge quality

6.High profile retention ability

7.Long dressing interval

Application machines

(1) Universal Cutter Grinder :CUTTERMASTERS,DECKEL,MICHAEL DECKEL,ISOG,VEVOR,Shars,MRCMWARCO,EWAG,Anca,Cincinnati,Griffo,Haro,Hawema,Huffmann,Jungner,Kirner,Rollomatic,Saacke,Gebr.,Safag,Wadkin,Walter,Schneeberger,Schutte,Sorenco,Stausak,Stream,Tacchella,Viking,Tempo,Straussak,Stream,Watkins

(2) CNC tool grinding machine : 2-axis,3-axis,4-axis,5-axis,6-axis CNC tool grinding machine

-

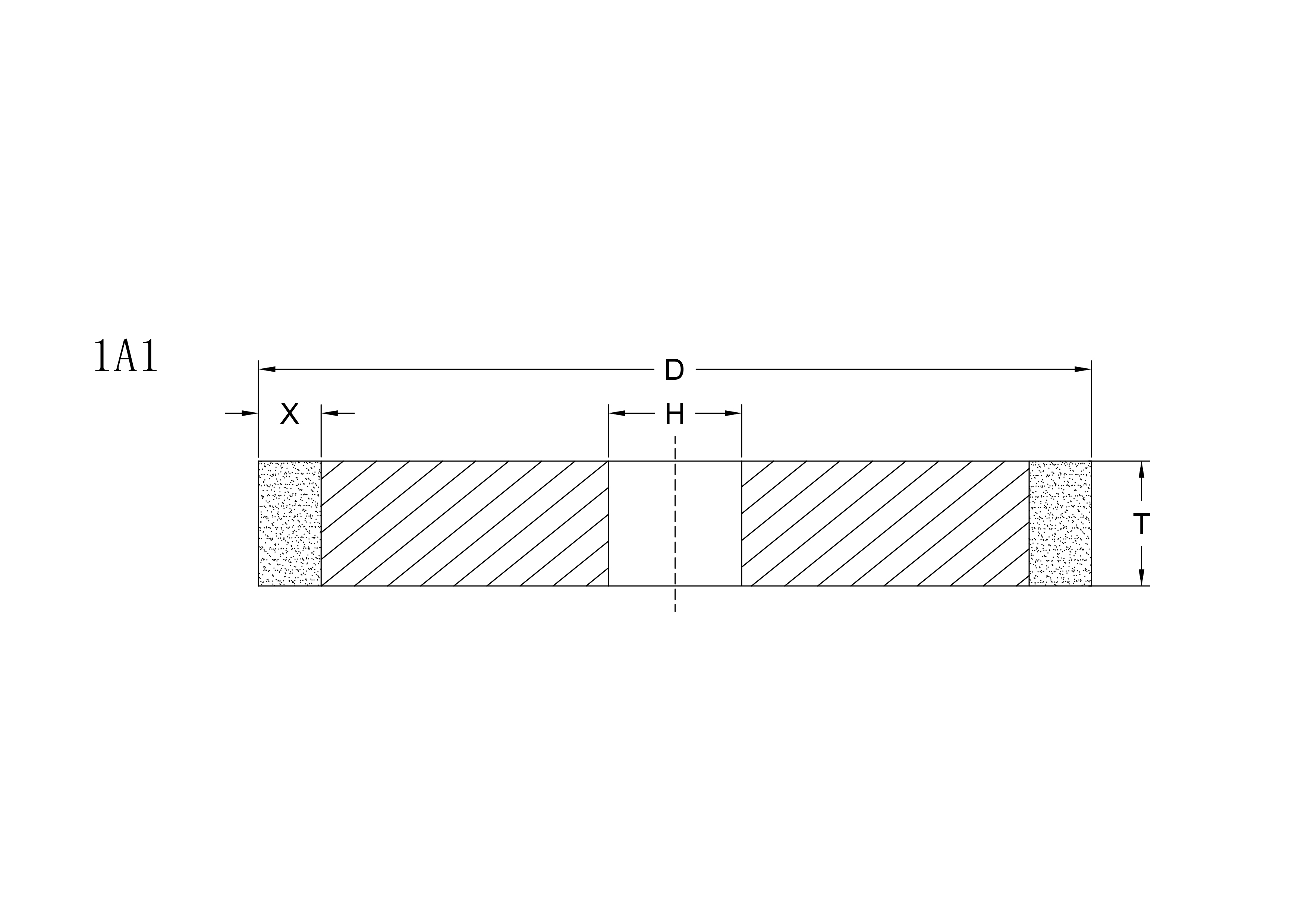

Metalworking Tools Sharpening Diamond CBN Wheels

-

Resin Diamond Grinding Wheels For Carbide Milli...

-

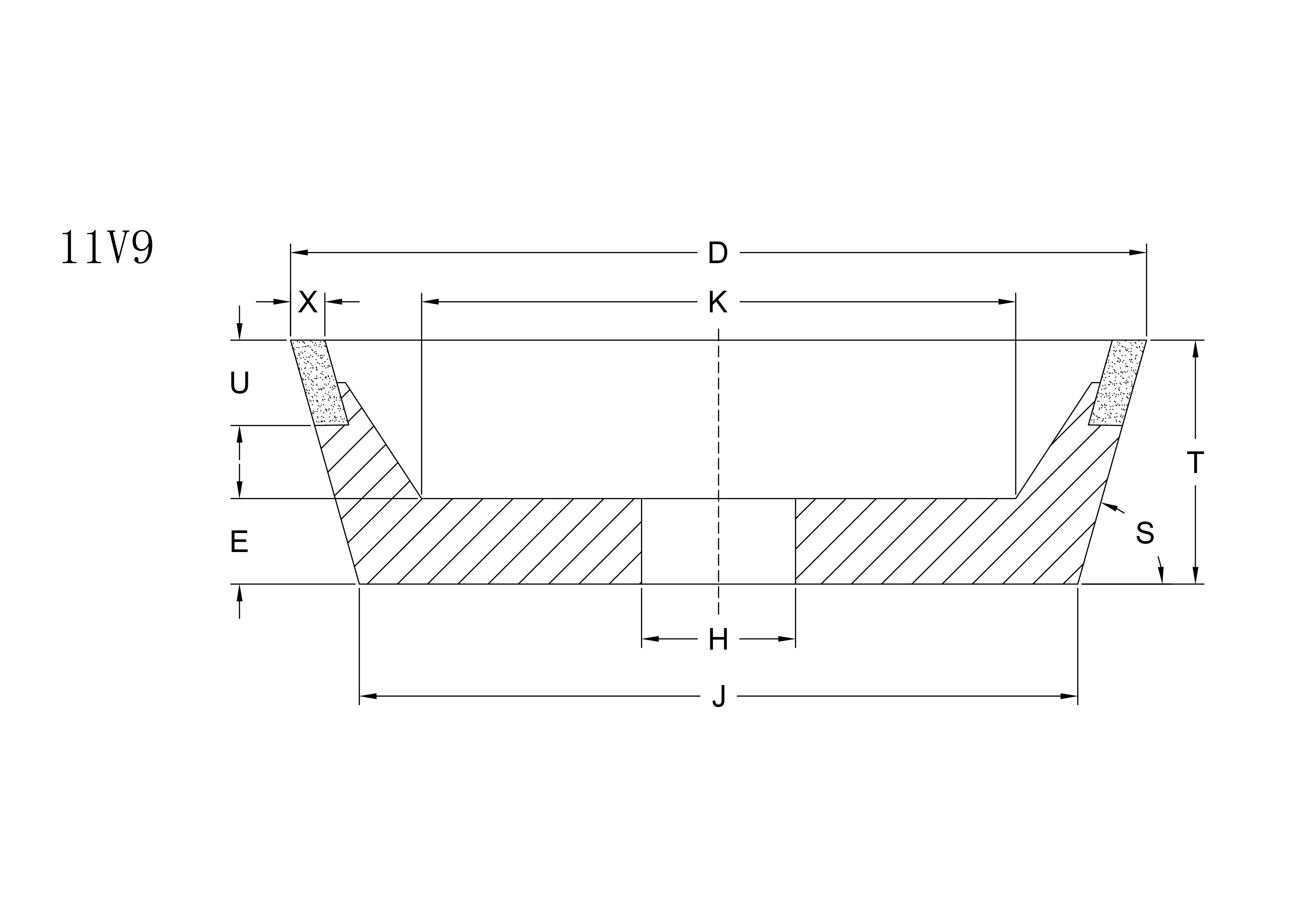

11V9 Resin Diamond Grinding Wheel For Universal...

-

12A2 Resin Diamond Grinding Wheel For Universal...

-

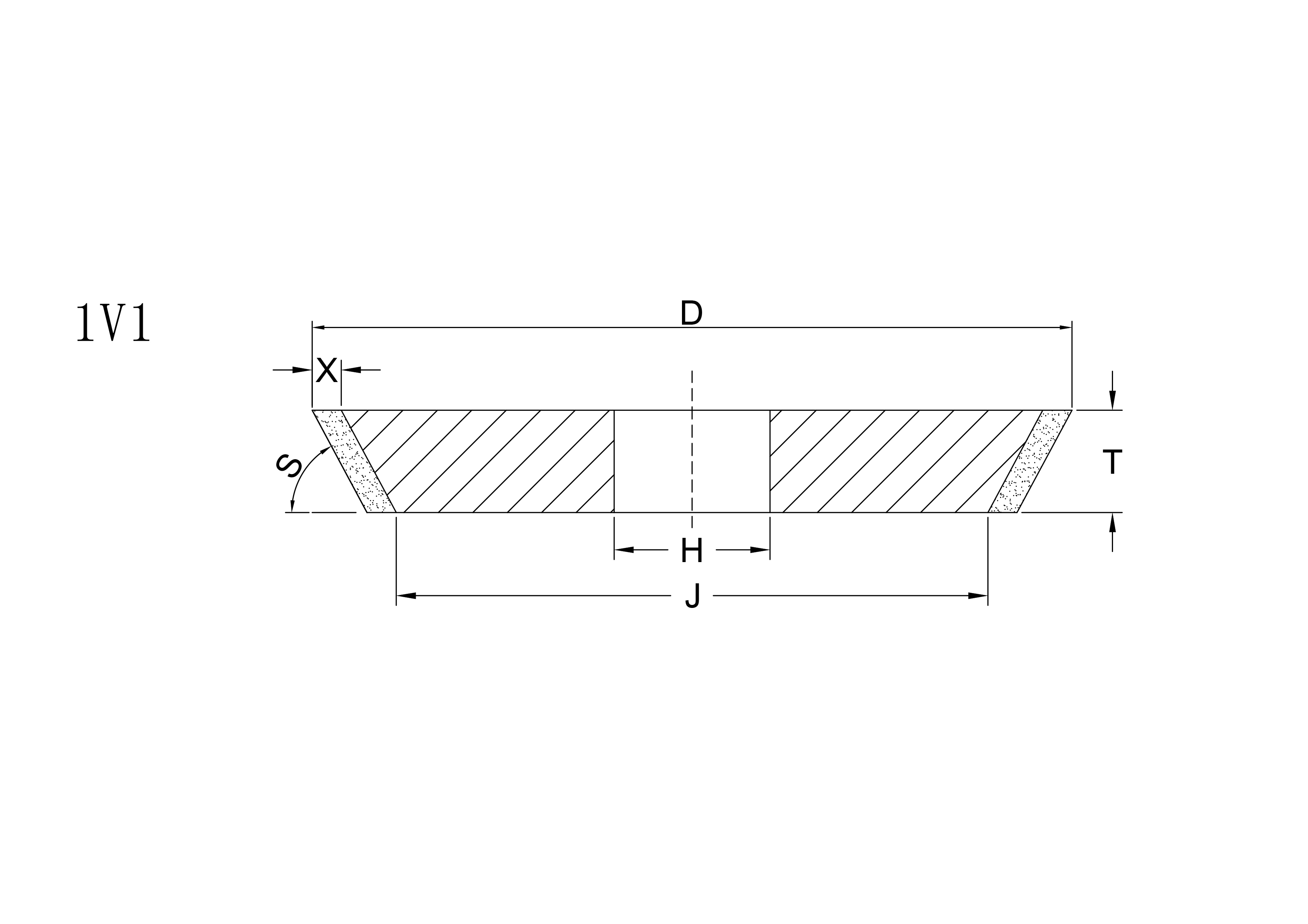

Metalworking 1V1 Resin Diamond Grinding Wheel f...

-

Diamond CBN Grinding Wheel for CNC Tool Grinder