Valve base cutting

Using profile CBN high speed grinding wheel to cut the stem of engine valve in order to control the total length of engine valve. Metal CBN grinding wheel havev high material removal, good shape retention, is the ideal tool for cutting valve base. Using Moresuperhard metal CBN grinding wheel to achieve profile accuracy.

Valve Disc end face grinding

Metal CBN grinding wheel with fine grit is suitable for finish grinding the end face of vlave disc.

Valve keeper groove grinding

Many varieties of valves (including the valve with asymmetric groove shape of the keeper groove) contain the keeper groove in the quenching area of the rod end. Considering the stress effect of hot processing on the keeper groove, the keeper groove shape is often processed by forming the keeper groove grinding after quenching. Therefore, it is an effective way to ensure the machining accuracy of the air lock groove by using the forming grinding method of the valve keeper groove.

|

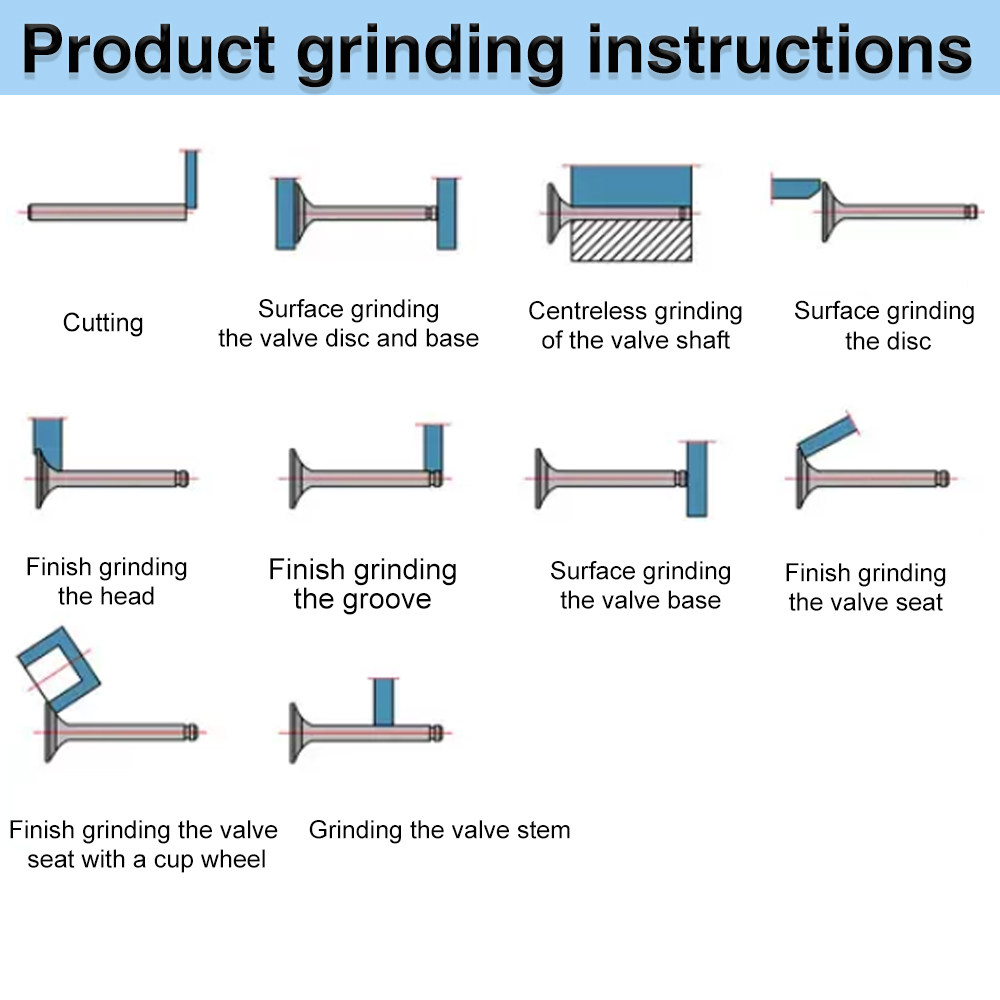

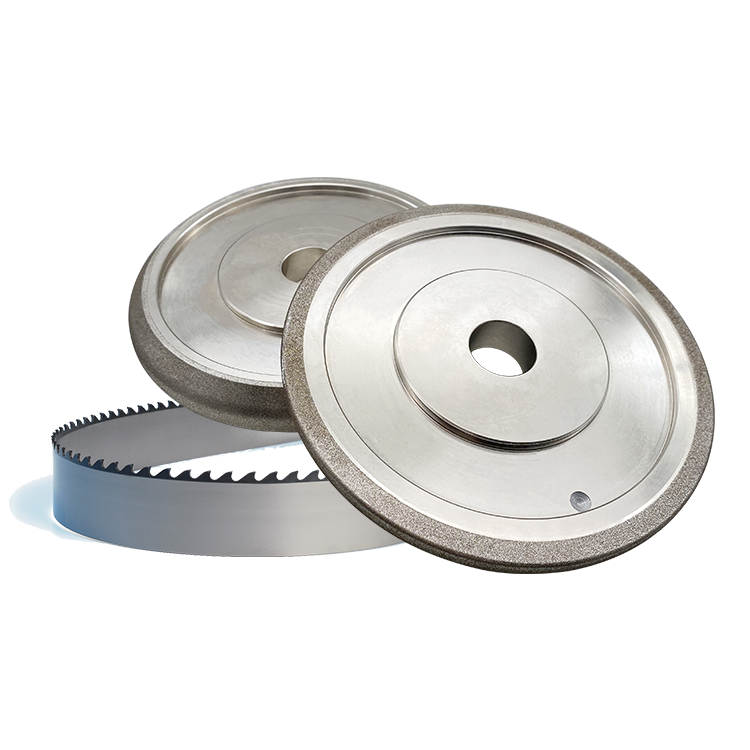

1.The grinding wheels are used to process engine valves (inlet valves and exhasut valves) in cars, motorcycles, trucks, and other engine valves.

2. Used for the forming grinding of the engine lock slot,neck,tapered surface,and the end surface of the engine valve,as well as the cutting off and multiparts processing, including valve groove wheel, Valve Tip End Grinding wheel, Chamfering wheel for Round Shaft and Tube, Valve Head & Seat Grinding tool, Valve Cut Off wheel.

3.Suitable for processing 40Cr. 4Cr9Si2. 4Cr1OSi2Mo.21-4N, 23-8N and other ordinary alloy steel and heat-resistant alloy steel.

-

Electroplated Diamond Grinding Wheels For Wire ...

-

Electroplated Diamond CBN Grinding Wheels CBN G...

-

1V1 Electroplated Taper Edge Diamond CBN Grindi...

-

Electroplated Flat Diamond Grinding Wheel for G...

-

12A1 Wafer hub dicing saw blade Diamond Dicing ...

-

Electroplated diamond CBN grinding wheel for ba...