Woodworking tools grinding wheels include

– Diamond & CBN wheels for circular saw grinding (face grinding, top grinding, flank grinding, hollow tooth grinding and re-sharpening )

– CBN grinding wheels for band saw sharpening

– CBN/ Diamond Chainsaw sharpening wheel

– CBN Wheel for woodturner tools sharpening

Parameters

|

D |

T |

H |

X |

||

|

(mm) |

Inch |

(mm) |

Inch " |

||

|

100 |

4" |

5 - 25.4 |

.2 - 1" |

TO YOUR REQUEST |

3-12mm |

|

150 |

6" |

5 - 25.4 |

.2 - 1" |

3-12mm |

|

|

175 |

7" |

5 - 25.4 |

.2 - 1" |

3-16mm |

|

|

200 |

8" |

5 - 50.8 |

.2 - 2" |

3-16mm |

|

|

250 |

10" |

5 - 50.8 |

.2 - 2" |

3-20mm |

|

|

300 |

12" |

10 - 50.8 |

.4 - 2" |

3-20mm |

|

|

350 |

14" |

10 - 50.8 |

.4 - 2" |

3-20mm |

|

|

400 |

16" |

10 - 50.8 |

.4 - 2" |

3-20mm |

|

|

450 |

18" |

10 - 50.8 |

.4 - 2" |

5-20mm |

|

|

500 |

20" |

16 - 50.8 |

.6 - 2" |

10-20mm |

|

|

600 |

24" |

16 - 50.8 |

.6 - 2" |

10-20mm |

|

Features

1. Good self-sharpening and sharp cutting

2. High efficiency and high precision

3. High resistence and best polishing

4. Low roughness of work piece surface

5. Less heat generating

6. Without burning work piece

Application

Circular saw blade grinding wheel:

TOP Grinding

Common models:6AA2、12A2、4A2、6AA9

Face Grinding

Common models:12V9、12V2、15V9、12A2、4A2

Side Grinding

Common models:1A1、3A1、14A1、6A2、6A9

Applicable machine brand: Wright, Vollmer, Wood-Mizer, ABM, Colonial Saw, Armstrong, Amada, Cooks, WOODLAND MILLS, TimberKing, WESTRON, MVM, Holzmann, NEVA, ISELI, Hud-Son, ZMJ, YOKEN.

Saw blade applicable: Simonds, Lenox, Wood-Mizer, Dakin-Flathers Ripper, Timber Wolf, Lenox Woodmaster, Munkfors, Fenes, Armoth, Ro-Ma, Wintersteiger, MK Morse, Forezienne, Bacho, Pilana, Disston, Ellis, Norwood, Baker.

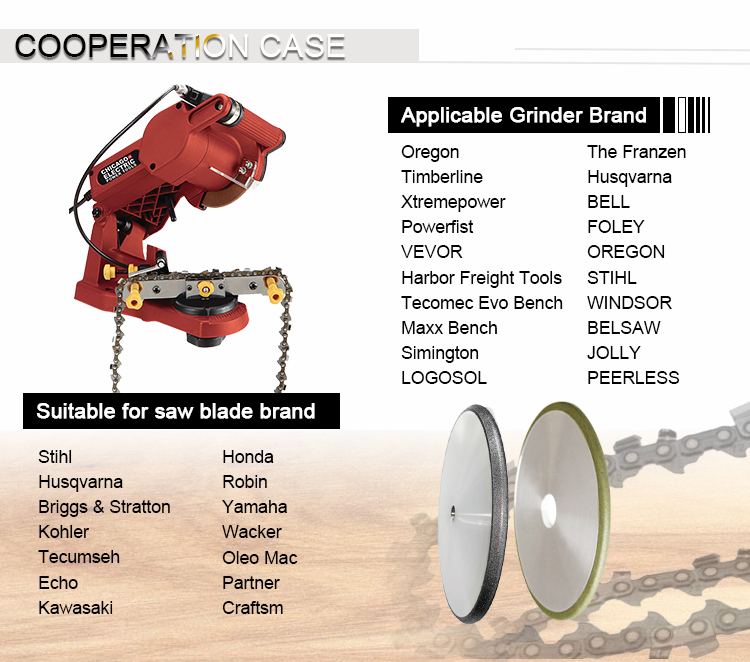

Applicable machine brand: Oregon, Timberline, Xtremepower, Powerfist, VEVOR, Harbor Freight Tools, Tecomec Evo Bench, Maxx Bench, Simington, LOGOSOL, The Franzen, Husqvarna, BELL, FOLEY, STIHL,WINDSOR, BELSAW, JOLLY, PEERLESS, TECOMEC, MAXX, ROUGHNECK, TIMBER TUFF, EFCO, NEILSEN - BELL, SILVEY, TOTAL.

Saw blade applicable: Stihl, Husqvarna, Briggs & Stratton, Kohler, Tecumseh, Echo, Kawasaki, Honda, Robin, Yamaha, Wacker, Oleo Mac, Partner, Craftsm, Husqvarna.

FAQ

1. What are the main products offered by Zhengzhou Ruizuan Diamond Tools Co., Ltd.?

We specialize in a range of high-quality diamond tools, including diamond grinding wheels, CBN grinding wheels, and PCD/CBN tools. Our products are designed to provide exceptional performance and durability across various applications.

2. How do I select the right grinding wheel for my application?

Choosing the right grinding wheel depends on several factors, including the material being ground, the desired surface finish, and the grinding operation (e.g., roughing, finishing). Our team can help you select the appropriate wheel based on your specific needs. Contact us with details about your application for personalized recommendations.

3. How do I maintain and care for my diamond and CBN grinding wheels?

Proper maintenance includes:

Regular cleaning: Remove debris and buildup to maintain performance.

Correct storage: Store in a dry, stable environment to prevent damage.

Proper usage: Follow recommended speeds and feeds to avoid excessive wear or damage.

4. Can I get customized diamond and CBN tools for my specific needs?

Yes, we offer customized solutions to meet your specific requirements. Whether you need a particular size, shape, or bond type, we can tailor our products to suit your application. Please contact us with your specifications for a custom quote.

5. What should I do if I encounter issues with my grinding wheels or tools?

If you experience any issues with our products, please contact our customer support team. We are committed to providing high-quality products and excellent service. Our experts will assist you in diagnosing and resolving any problems.

5.What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment. The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

6. How can I place an order or request a quote?

You can place an order or request a quote by visiting our website and filling out the contact form, or by directly contacting our sales team via email or phone. Provide details about your requirements, and we will respond promptly with pricing and availability information.