-

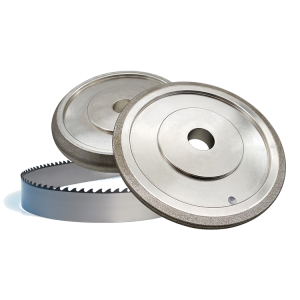

Electroplated diamond CBN grinding wheel for band saw blade

Electroplated CBN band saw sharpening wheel is coated with CBN(Cubic Boron Nitride) on steel body,specially for band saw sharpening of any type.Electroplated cbn band saw sharpening wheel achieves superior performance, gives high quality finish. They are produced with steel core and electroplated (nickel bonded) rim. Lasts very long. Reduces band saw breaking. No need no profile, no dust. These wheels are perfect choice to grind band saws.

-

Resin Bond Diamond Grinding Wheel for Sharpening Tct Circular Saw Blades

Resin bond diamond grinding wheel is mainly used for surface grinding ,cylindrical grinding of hand carbide measuring tools ,cutting tools,moulds and also for plunge-cut grinding as well as for grinding. We have much experience in woodworking industry machining.Mainly used for the grinding of circular saw blade, disc saw, chainsaw,bandsaw , etc.

-

6A2 diamond & cbn vitrified bonded wheel For PCD Pcbn Cutting Tools Grinding

Vitrified bonds allow the wheel to be very rigid, strong and porous. These characteristics each provide many benefits to the wheel. Having a rigid wheel allows for a strong cutting performance and increased grinding speed. Another added benefit of the vitrified bond is its porous character. The porosity of the wheel allows coolant to penetrate between the work piece and the wheel to effectively remove heat from the point of contact, and we all know that any reduction in heat generated while grinding will extend the life of the product.

-

1A1 Resin Bond Diamond Grinding Wheel for PDC Drill Bits Drilling Tool

Resin Bond is the most common choice in Diamond and CBN super-abrasive wheels. It forms a bond structure that keep the wheel sharp cutting, super surface finish, efficient grinding and less heat generating. The most important is that it is very cost effective. It is more competitive than Vitrified bond and Metal Bond. So it is broadly applied in the grinding industries.1A1 resin grinding wheel is mainly used in pdc drilling bit, pdc cutter/inserts, tungsten carbide coating/insert, caibide coating, hardfacing coating.

-

1F1 Resin Bond Diamond CBN Grinding Wheel for Carbide-Tipped Chainsaw

Resin bond diamond grinding wheel is mainly used for surface grinding ,cylindrical grinding of hand carbide measuring tools ,cutting tools,moulds and also for plunge-cut grinding as well as for grinding. We have much experience in woodworking industry machining.Mainly used for the grinding of circular saw blade, disc saw, chainsaw,bandsaw , etc.

-

11V9 Resin Diamond Grinding Wheel for Flywheel and circular saw blade

CBN 11V9 6 Inch Resin Bond Diamond Grinding Wheel for Metal Carbide Flywheel circular saw blade

-

Vitrified bond CBN Grinding Wheel For Crankshaft And Camshaft

Vitrified bond CBN grinding wheels are used for grinding the cam lobes and journals of automobile camshaft. Optimum bond specifications have been set for each type of cam material, and since the CBN wheels are used for high-speed grinding, bond quality, adhesives, and the materials used for the core are carefully designed for safety.

-

High Efficiency Diamond & CBN Metal Bonded Wheel Manufacturers

Metal bonded tools are created from the sintering of powdered metals and other compounds with either Diamond or Cubic Boron Nitride (CBN).This process produces an extremely strong product that holds its shape well during use. Metal Bond maintains a long and useful tool life with a reduction in the frequency of dressing. Generally, Metal Bond wheels have the hardest matrix, therefore it performs best in operations under flood coolant.

-

6A2 Vitrified Bond Diamond CBN Grinding Wheel For PCD PCBN Super-hard Cutting Tools

Vitrified Bond is a bonding Vitrified bond wheels are extremely aggressive and free cutting at low temperature. It is the most popular bonding for traditional abrasive grinding wheels, and as to superabrasive grinding wheels, it is an extremely high stock removing rates and extremely high wheel life.