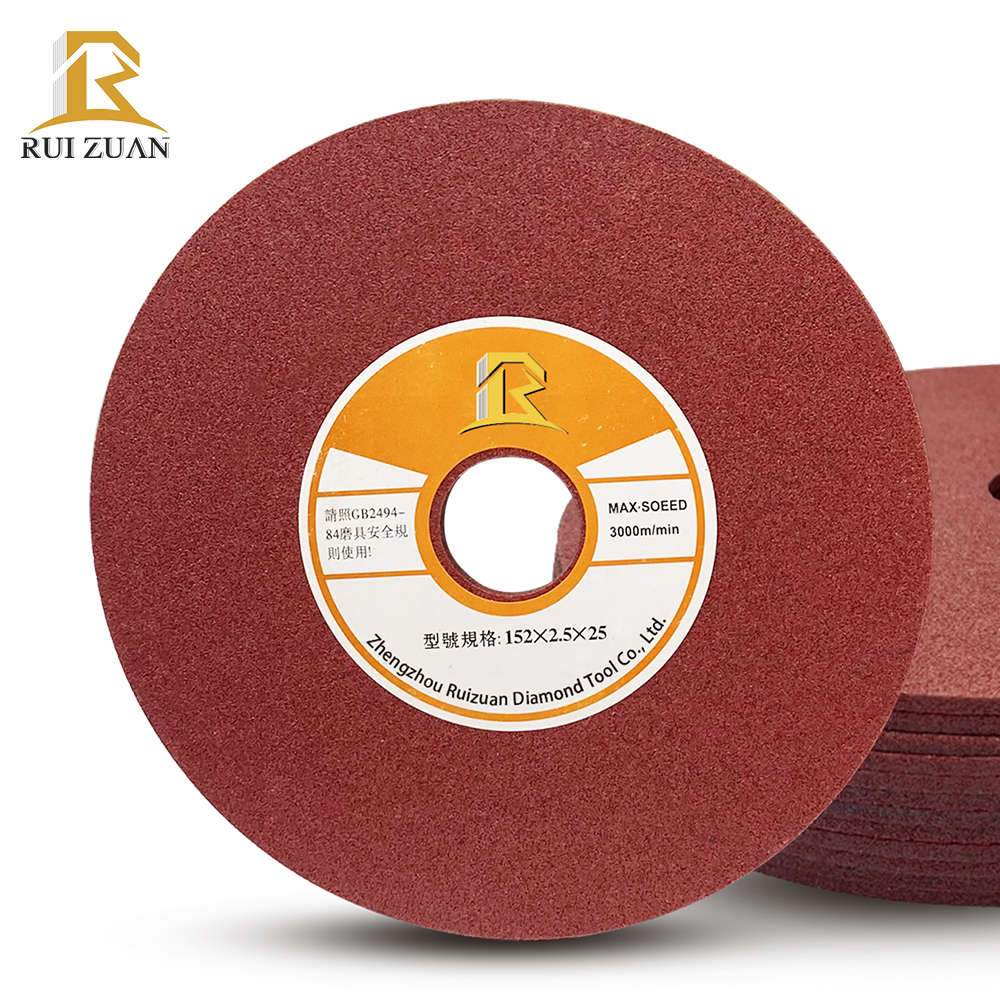

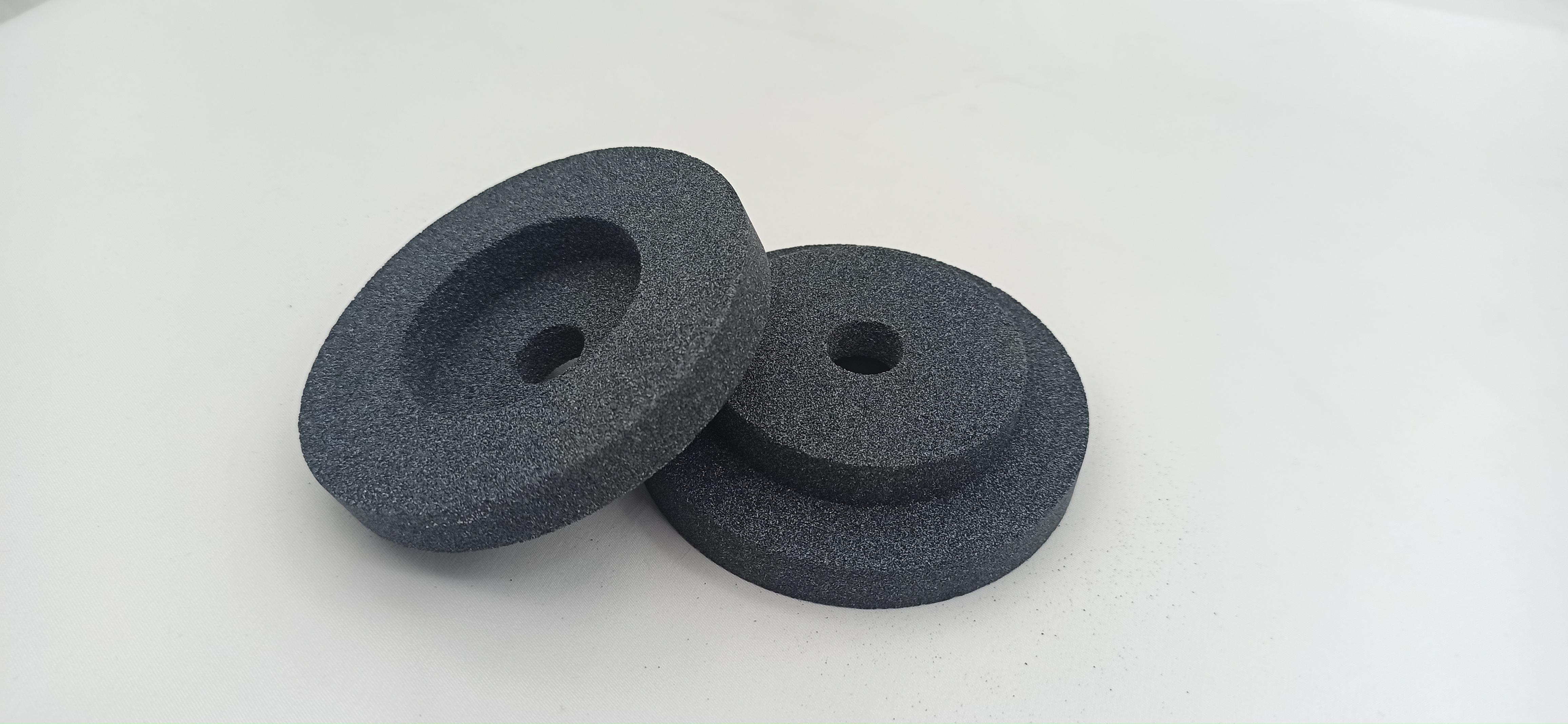

Grinding wheels can be used to grind the sealing surface, valve disc, valve seat and other parts of the valve to ensure their sealing performance and wear resistance.Valve grinding wheels are usually selected based on the type, grain size and structure of the abrasive, as well as the shape and size of the grinding wheel.

For the valve manufacturing and repair industry, choosing the right valve grinding wheel is crucial because it directly affects the processing quality and performance of valve components. Therefore, the correct selection and use of grinding wheels can improve work efficiency and extend the service life of valve parts, while ensuring the reliability and safety of the valve.

|

||||||||

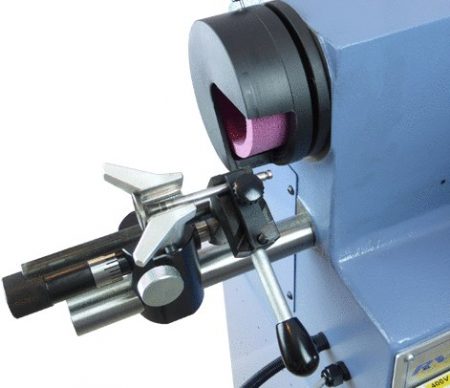

Engine Valve Grinding Wheel,specifically engineered and manufactured for valve face grinding,valve shaft centerless grinding,valve head & seat grinding,valve groove & tip raduis grinding

Suitable for different valve machines:SVSII-D series machines,241 Series Valve Refacer ,Fits all Black & Decker Valve Refacer Models A, B, C, LW, M, MW, N, NW and NWB