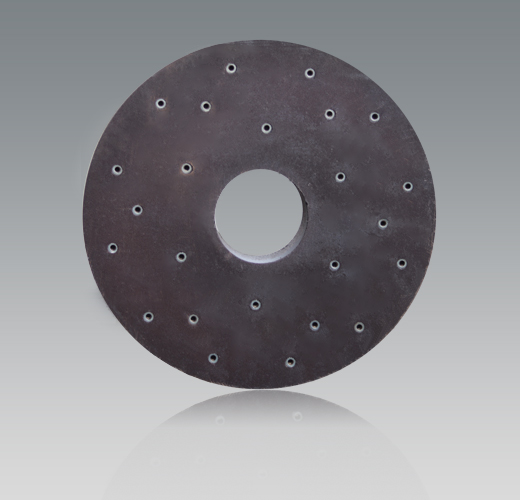

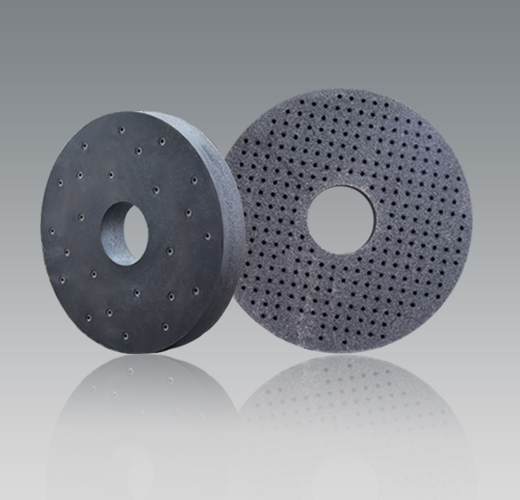

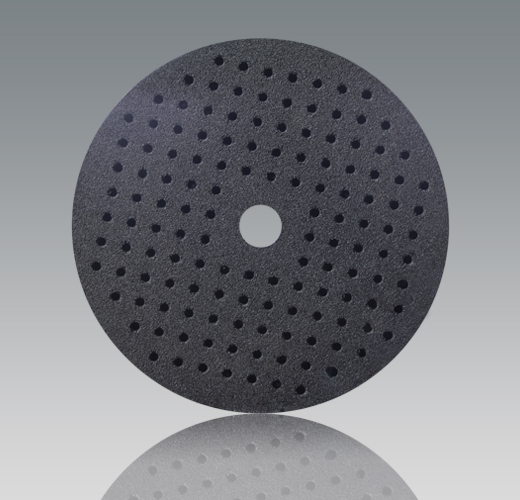

Spring End Grinding Wheel

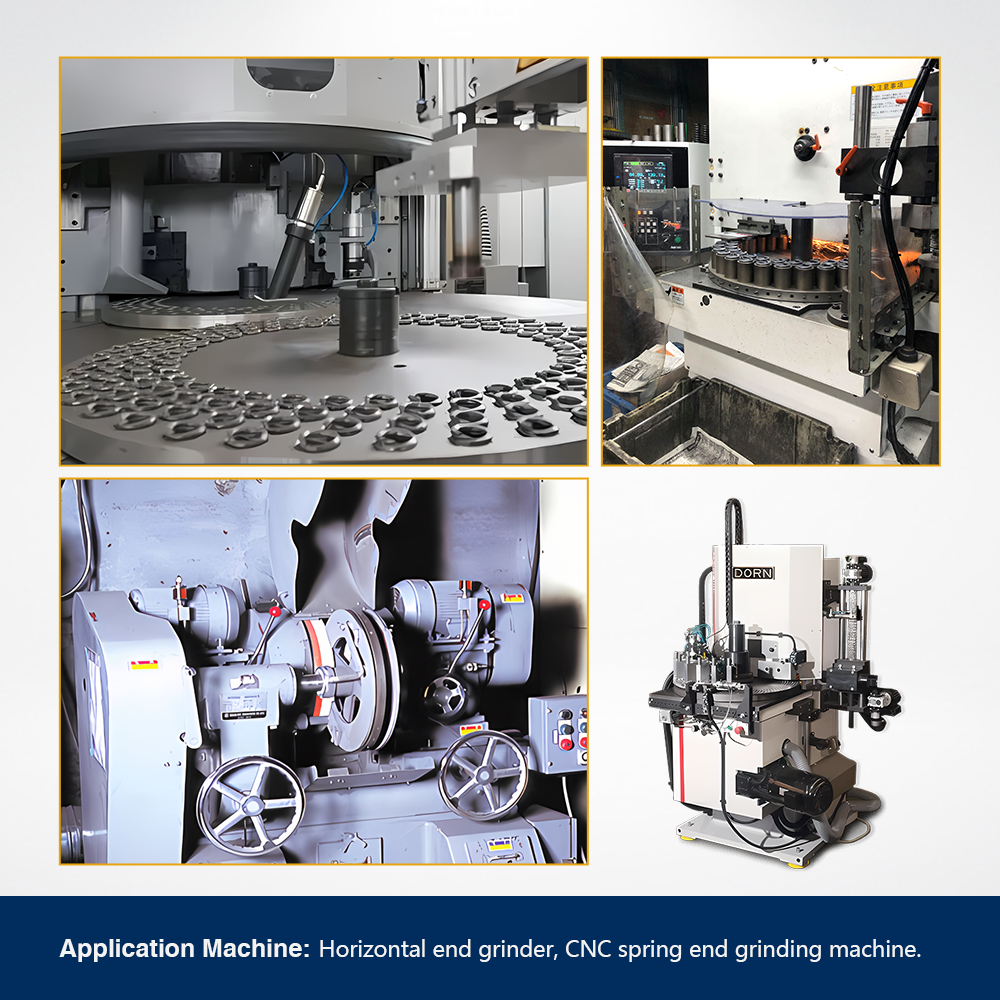

One of the final stages in the production of springs is the operation of spring end grinding.

The grinding wheel for spring is a kind of abrasive tools with resin as a binding agent. Because the components being processed are special spring steel with high hardness and high quenching degree. If the hardness of the grinding wheel is low, it will easy to break, poor safety, and fast wear. If the hardness of spring grinding wheel is high, although the grinding wheel is not easy to break, but easy to burn the workpiece, affecting the quality of the workpiece.Our spring grinding wheels are made of specially selected high-quality sand grains and have a long service life, which can greatly reduce your production input costs.

|

Mainly used for grinding various types of springs.

Workpiece Materials Of Spring:Spring steel, Stainless steel, High Carbon, Galvanized wire, Mild steel, high tensile Cr-Si

Bolt-tightening parallel grinding wheels are mainly suitable for grinding parts with smooth surfaces. The main grinding objects are: bearing rings, automobile friction plates, piston rings, engine cylinder heads, springs, connecting rods, compressor parts, etc.