Product Description

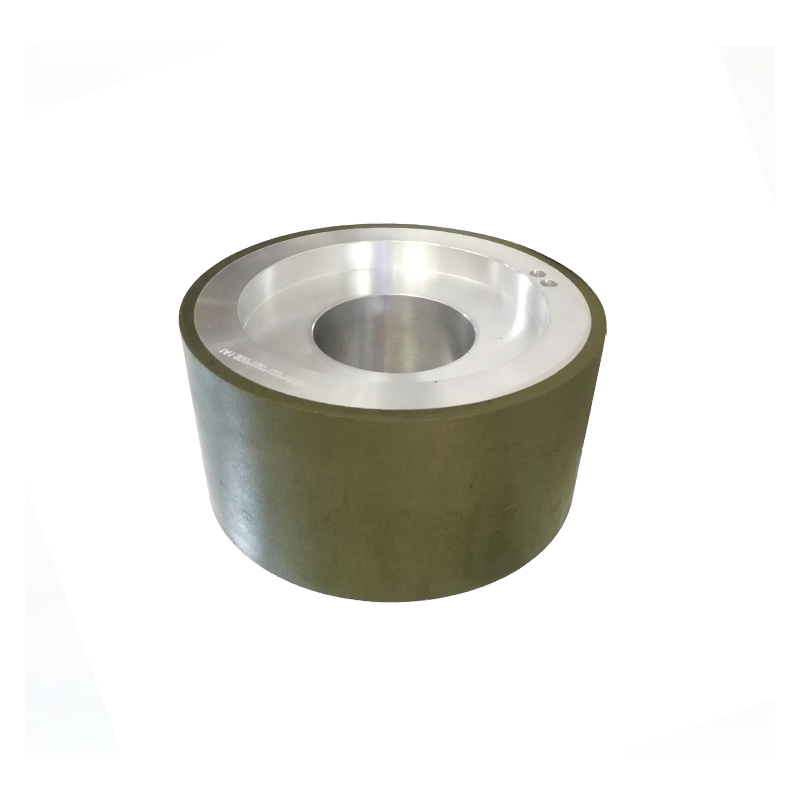

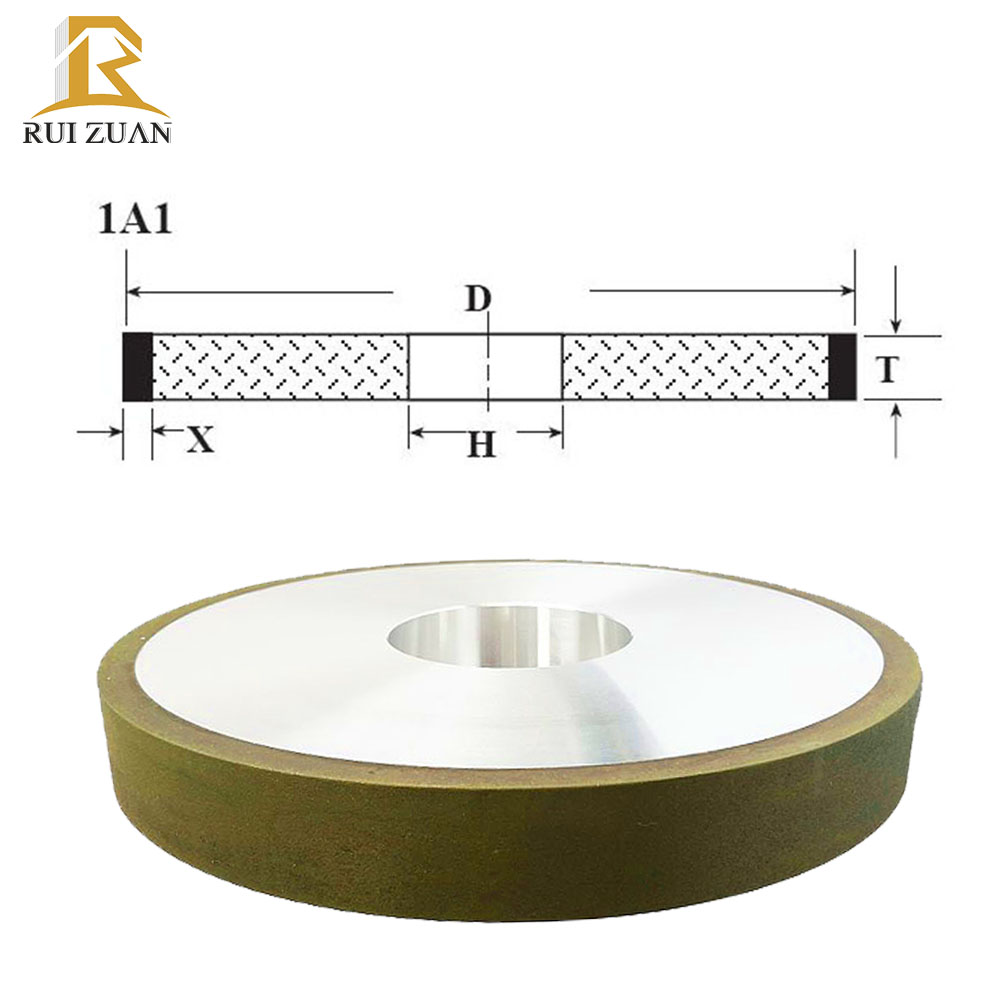

Resin Bond is the most common choice in Diamond and CBN super-abrasive wheels. It forms a bond structure that keep the wheel sharp cutting, super surface finish, efficient grinding and less heat generating. The most important is that it is very cost effective. It is more competitive than Vitrified bond and Metal Bond. So it is broadly applied in the grinding industries.1A1 resin grinding wheel is mainly used in pdc drilling bit, pdc cutter/inserts, tungsten carbide coating/insert, caibide coating, hardfacing coating.

Parameters

|

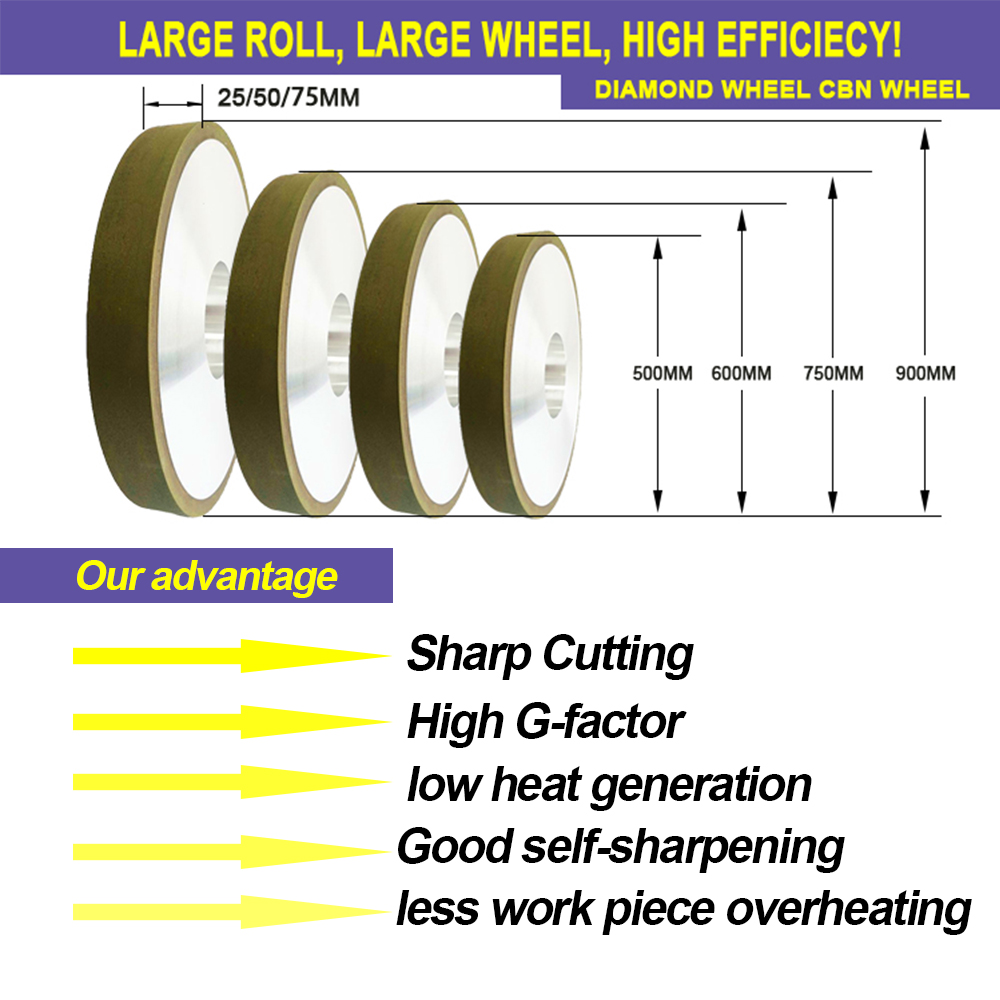

Popular Sizes

D x T x H x X |

D

(mm) |

T

(mm) |

H

(mm) |

X

(mm) |

|

2" x 1" x H

|

50.8

|

25.4

|

customize |

customize |

|

2.5" x 1" x H

|

63.5

|

25.4

|

||

|

3" x 1" x H

|

76.2

|

25.4

|

||

|

3.5" x 1" x H

|

88.9

|

25.4

|

||

|

4" x 1" x H

|

101.6

|

25.4

|

||

|

5" x 1" x H

|

127

|

25.4

|

||

|

6"x1"x1-1/4"x1/2"

|

150

|

25.4

|

31.75

|

12.7

|

|

7"x1"x1-1/4"x1/2"

|

175

|

25.4

|

31.75

|

12.7

|

|

8"X1"X1-1/4"X1/2"

|

200

|

25.4

|

31.75

|

12.7

|

|

10"X1"X1"X1/2"

|

250

|

25.4

|

25.4

|

12.7

|

|

12"x2"x5"x1/2"

|

300

|

50.8

|

127

|

12.7

|

|

14"x2"x5"x1/2"

|

350

|

50.8

|

127

|

12.7

|

|

16"x2"x5"x5/8"

|

400

|

50.8

|

127

|

16

|

|

20"x2"x12"x5/8"

|

508

|

50.8

|

304.8

|

16

|

|

24"X2"X12"X4/5"

|

610

|

50.8

|

304.8

|

20

|

|

30"x2"x12"x4/5"

|

750

|

50.8

|

304.8

|

20

|

|

36"x2"x12"x4/5"

|

900

|

50.8

|

304.8

|

20

|

Features

Our Advantages

Maintaining Downhole Tools with Diamond Wheels Downhole tools are of the utmost importance when it comes to the oil and mining industry.

The quality of downhole tools is key when comes to facing the difficult and technically challenging risks that companies face when discovering oil and minerals.

If the downhole tool is unreliable or in poor condition, it's not as simple as repairing in a matter of minutes. The whole tool must be removed from the deep hole it has drilled. Each passing minute of downtime cost the company thousands of dollars in lost productivity.

Application

Grinding Wheels for the Oil and Gas Industry

Using our proprietary bonds specifically for hardface and hardened alloys, we can provide the stock removal and surface finish you desire. Maintaining and working with virtually indestructible Thermal Spray coatings and other super hard materials is a challenging task, the best material to use for grinding thermal spray is the hardest known material, diamond. Specifically designed for thermal spray coatings, our DP-1 bond performs under the extreme stresses caused by grinding such a hard material. These wheels will provide the rapid stock removal and surface finish you need while maintaining a cost effective, efficient grinding solution.

FAQ

1. What are your prices?

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your company contact us for further information.

2.Do you have a minimum order quantity?

Yes, we require all international orders to have an ongoing minimum order quantity. If you are looking to resell but in much smaller quantities, we recommend you check out our website

3.Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

4.What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment. The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

5.What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal: For big orders, partial payment is also acceptable.